"We Machine The Future"

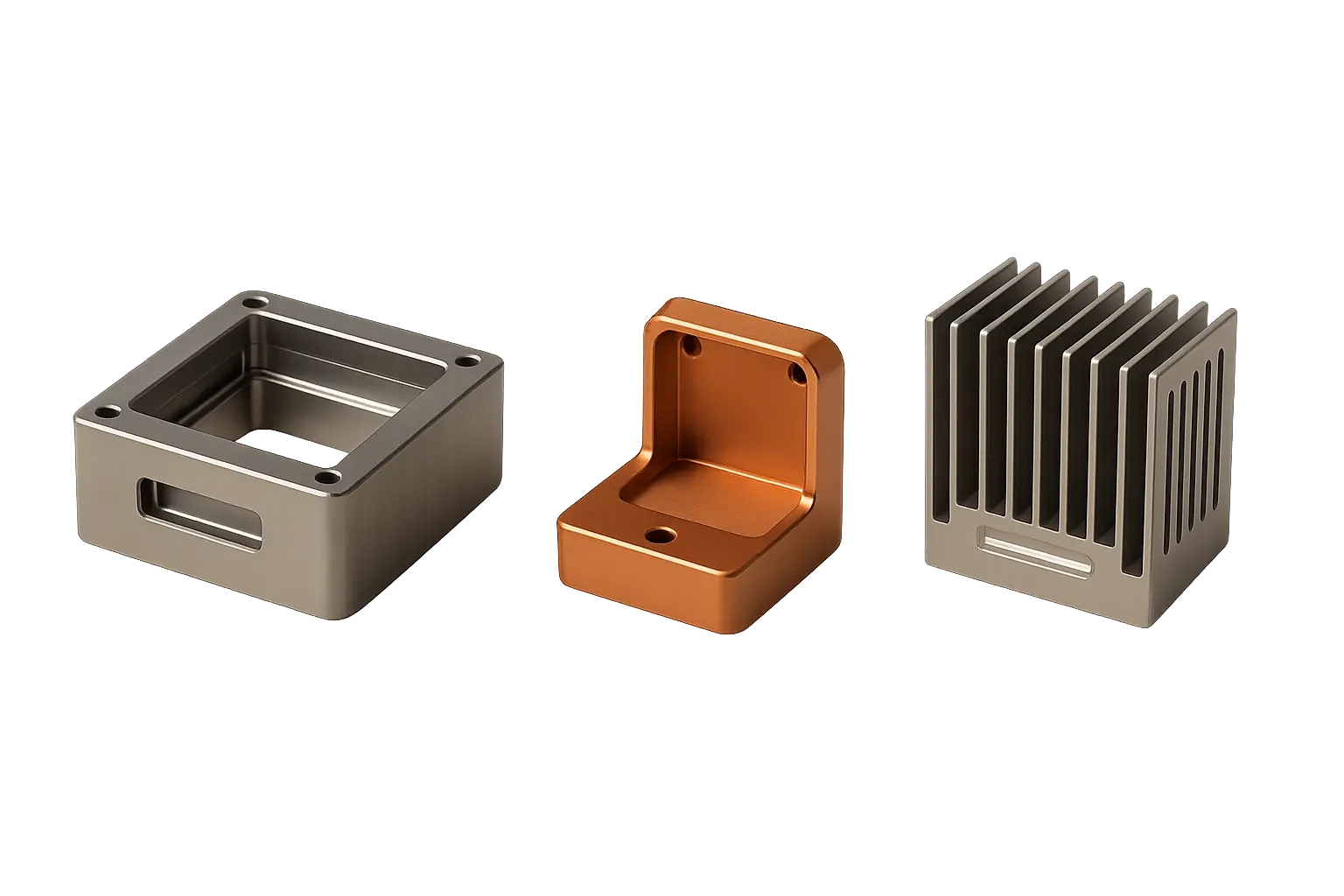

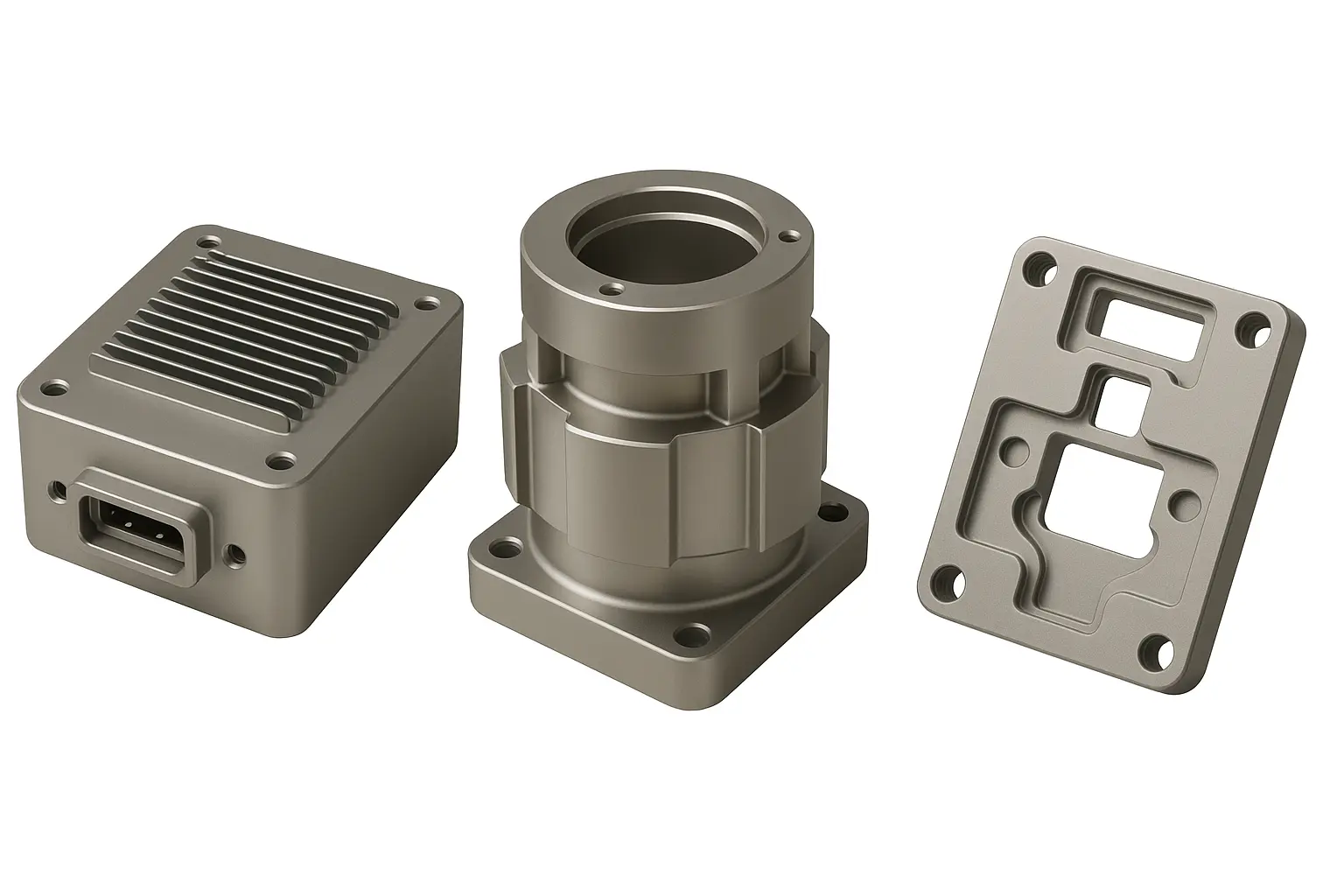

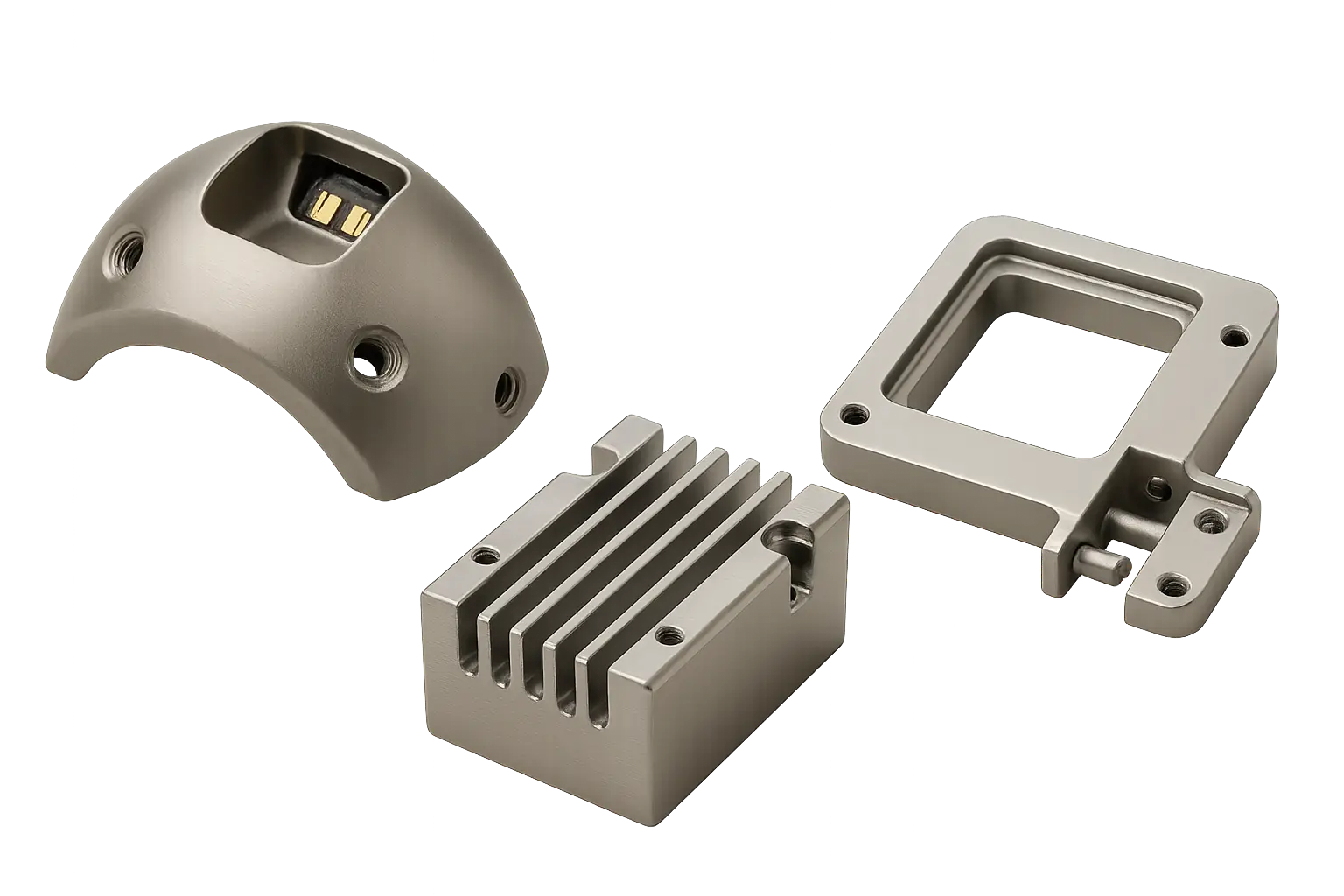

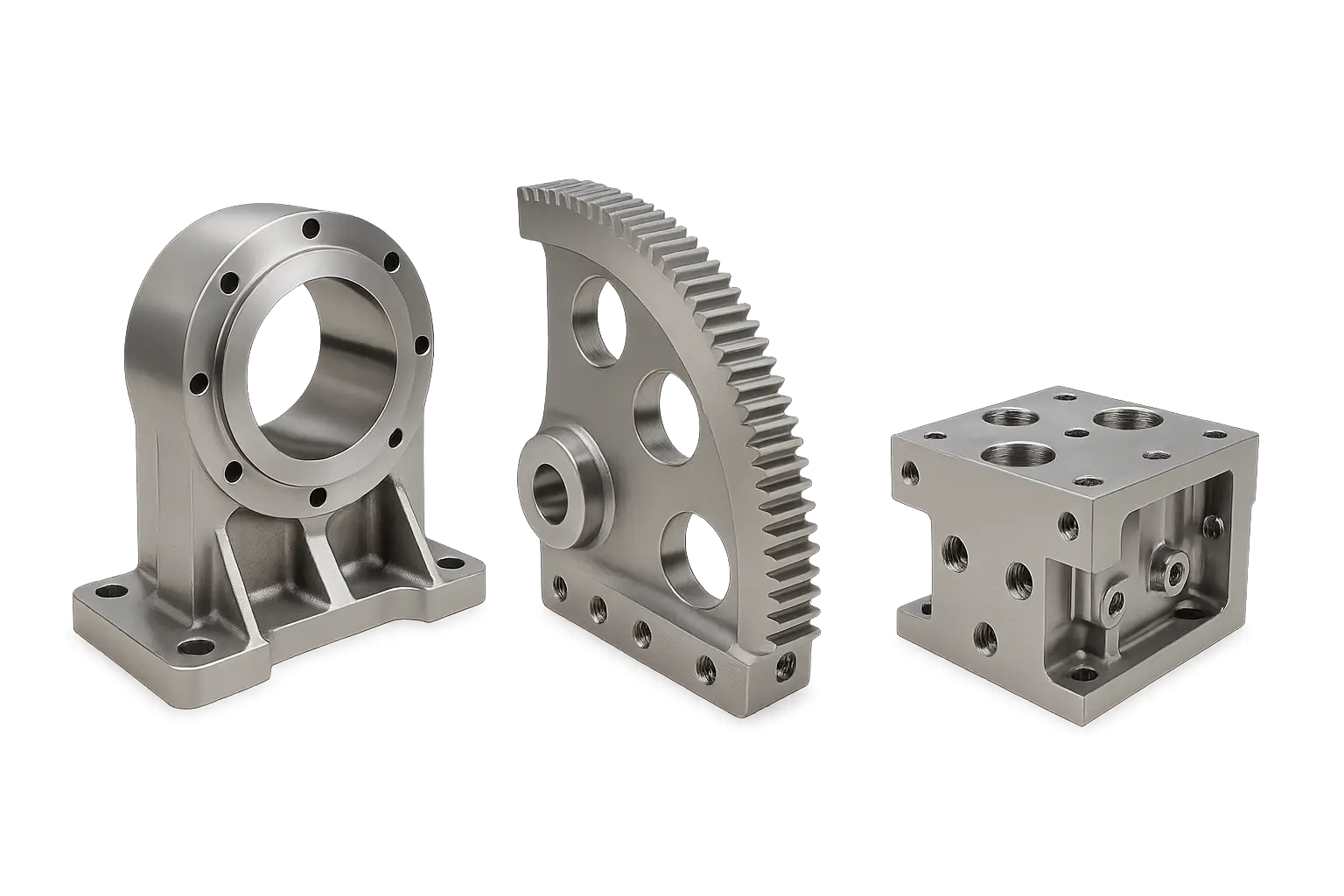

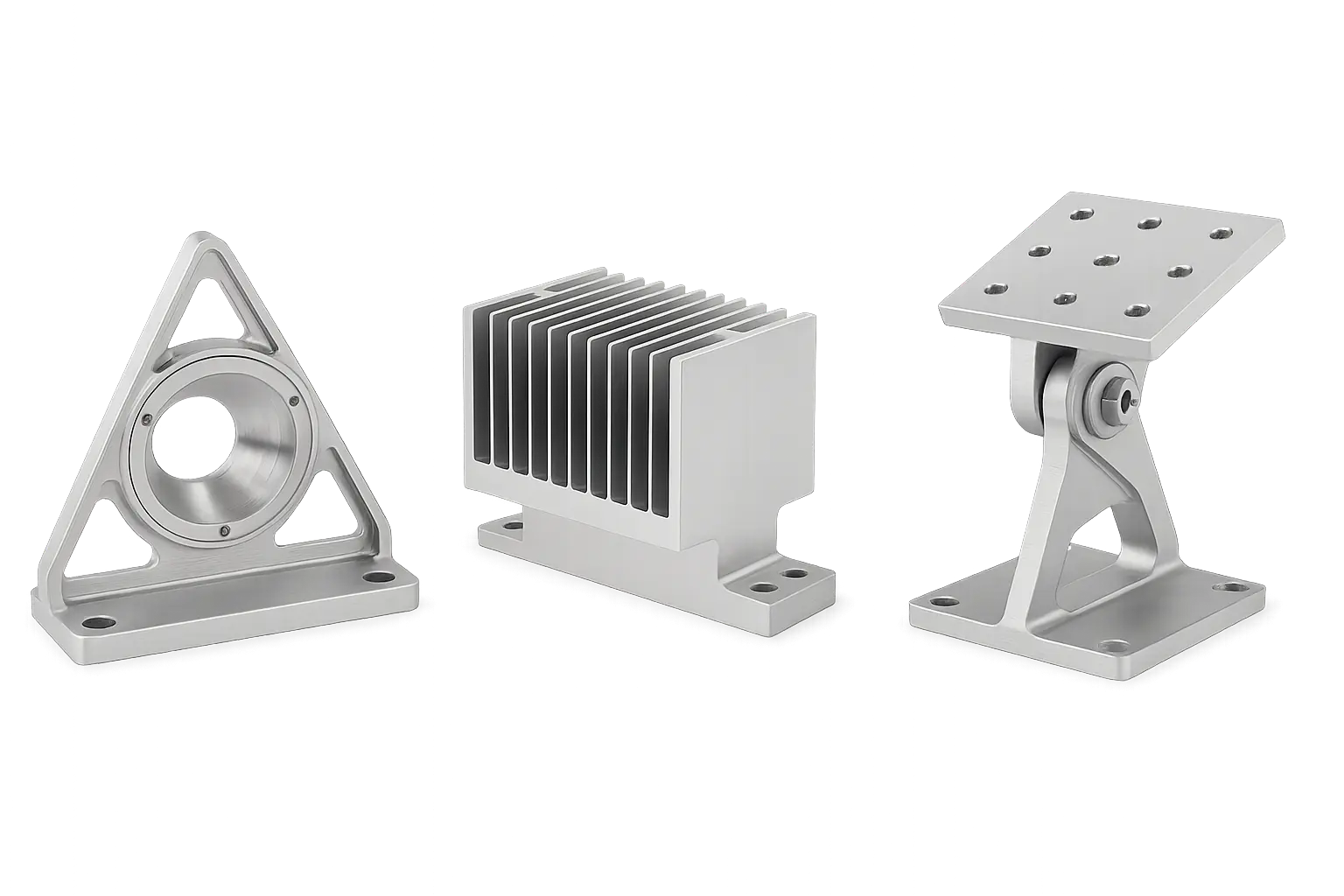

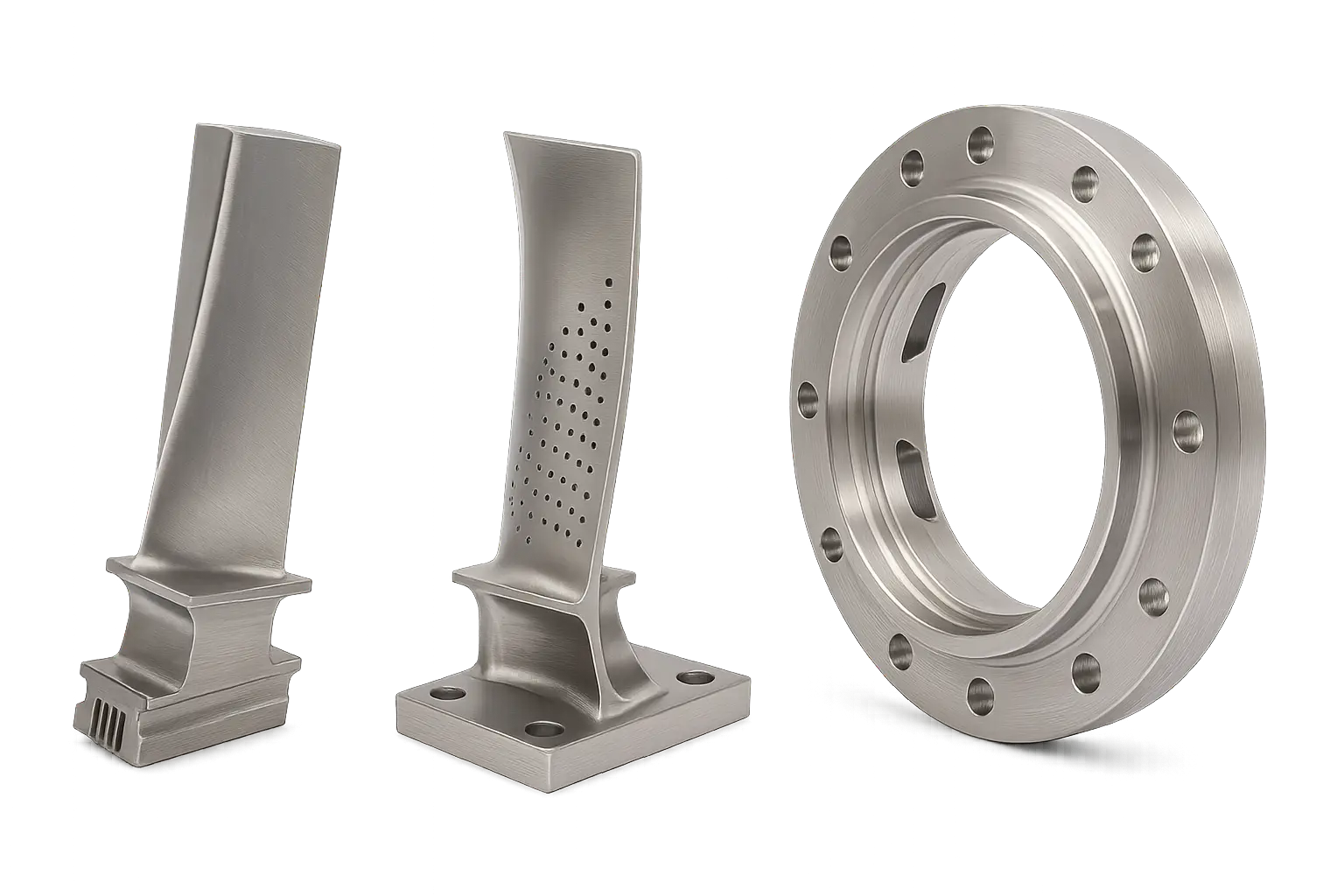

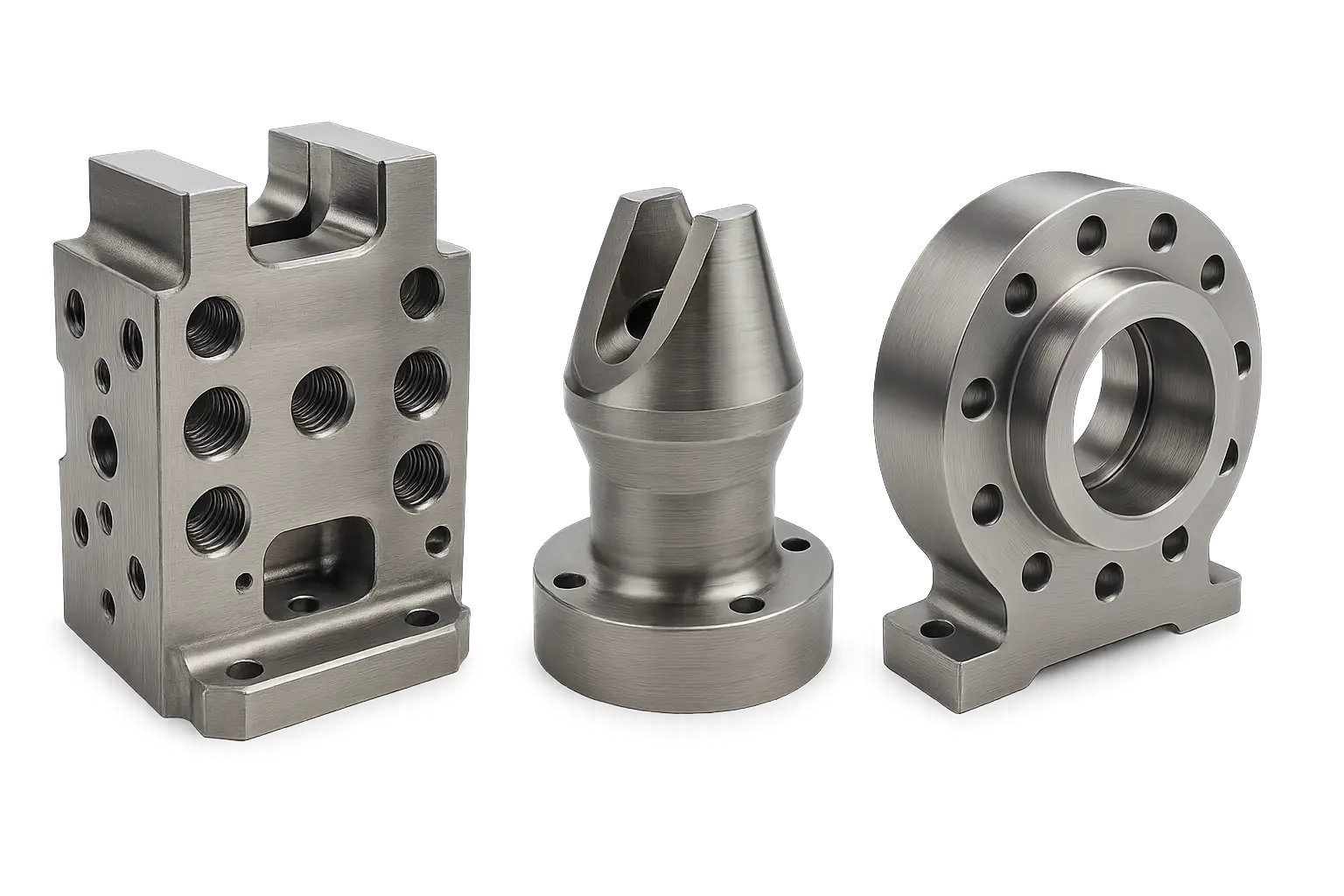

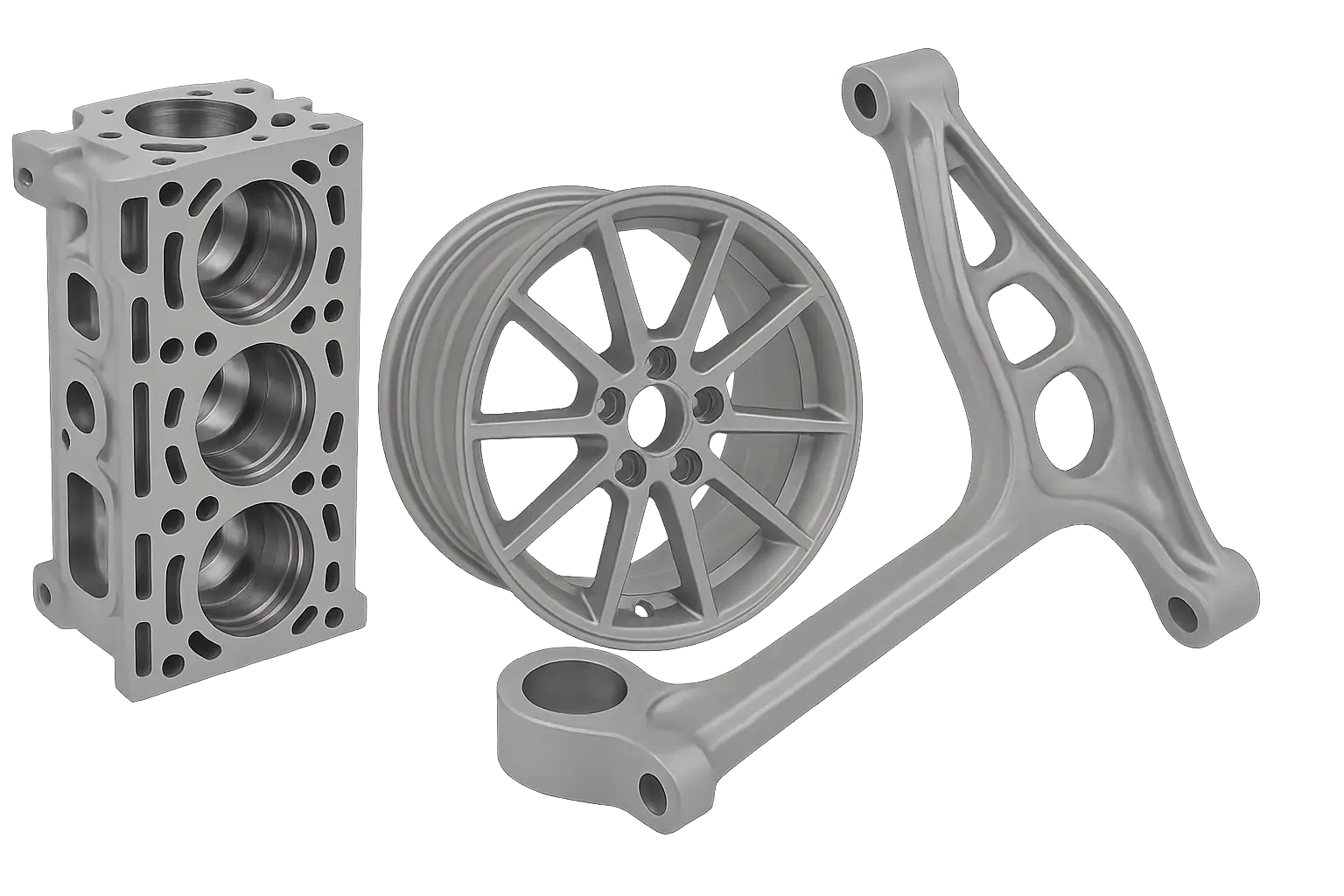

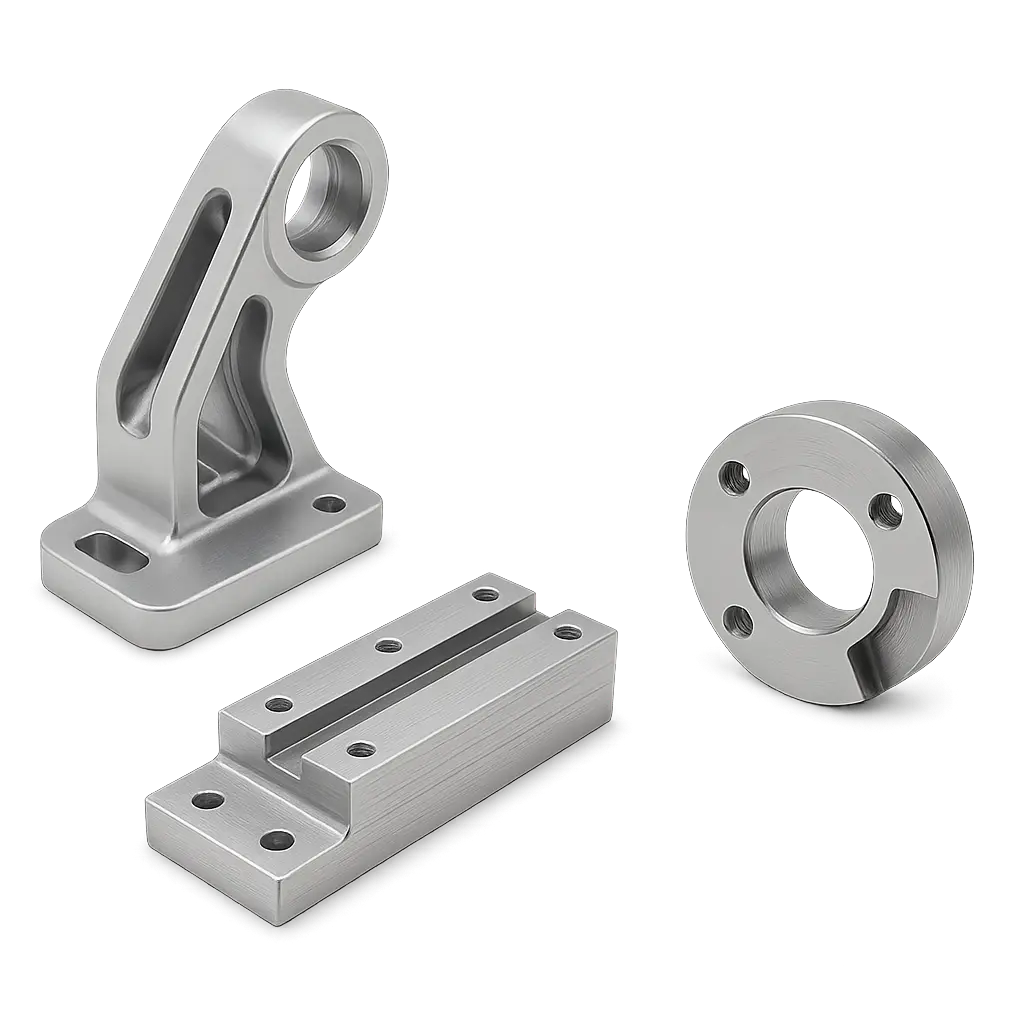

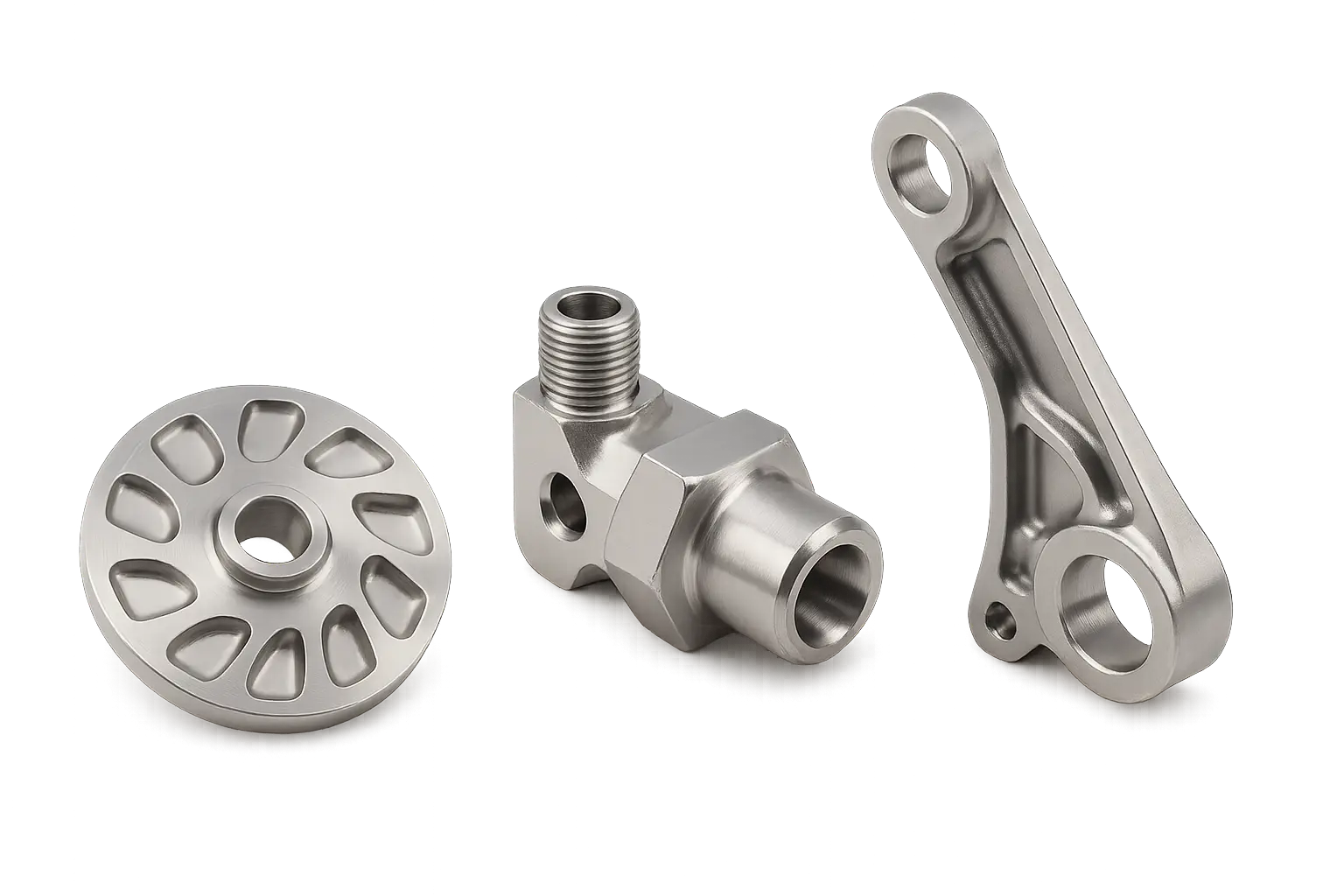

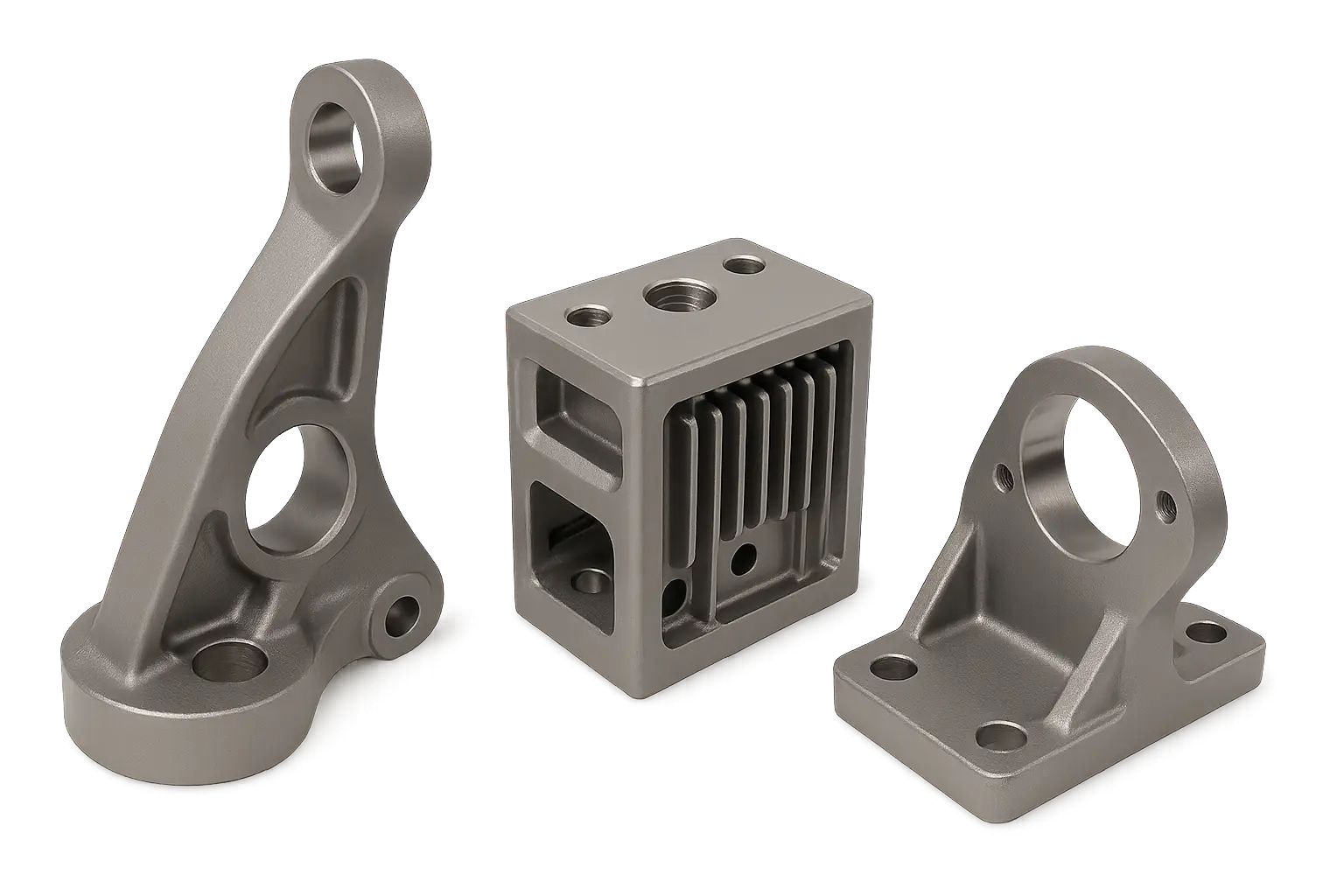

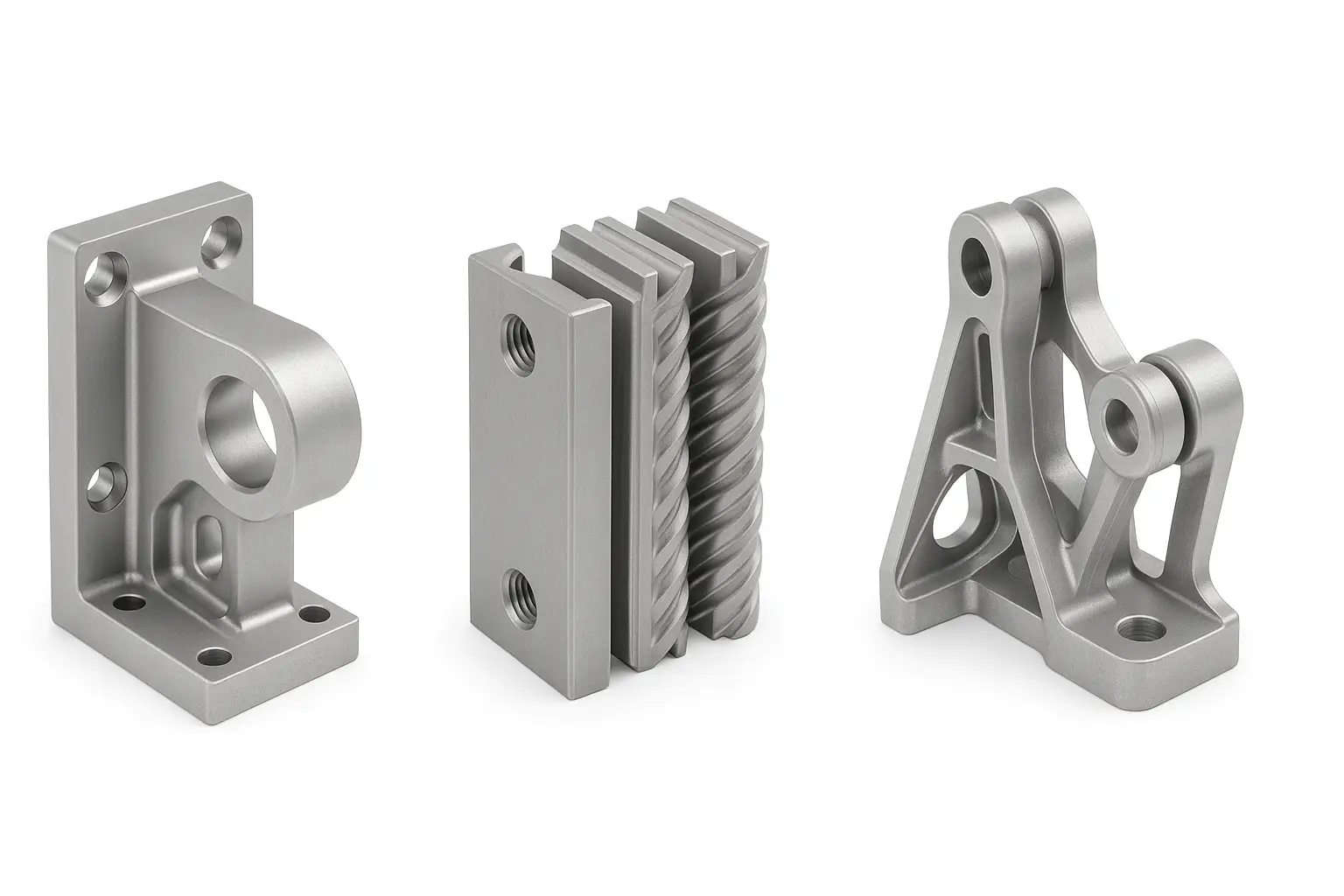

Production Capabilities

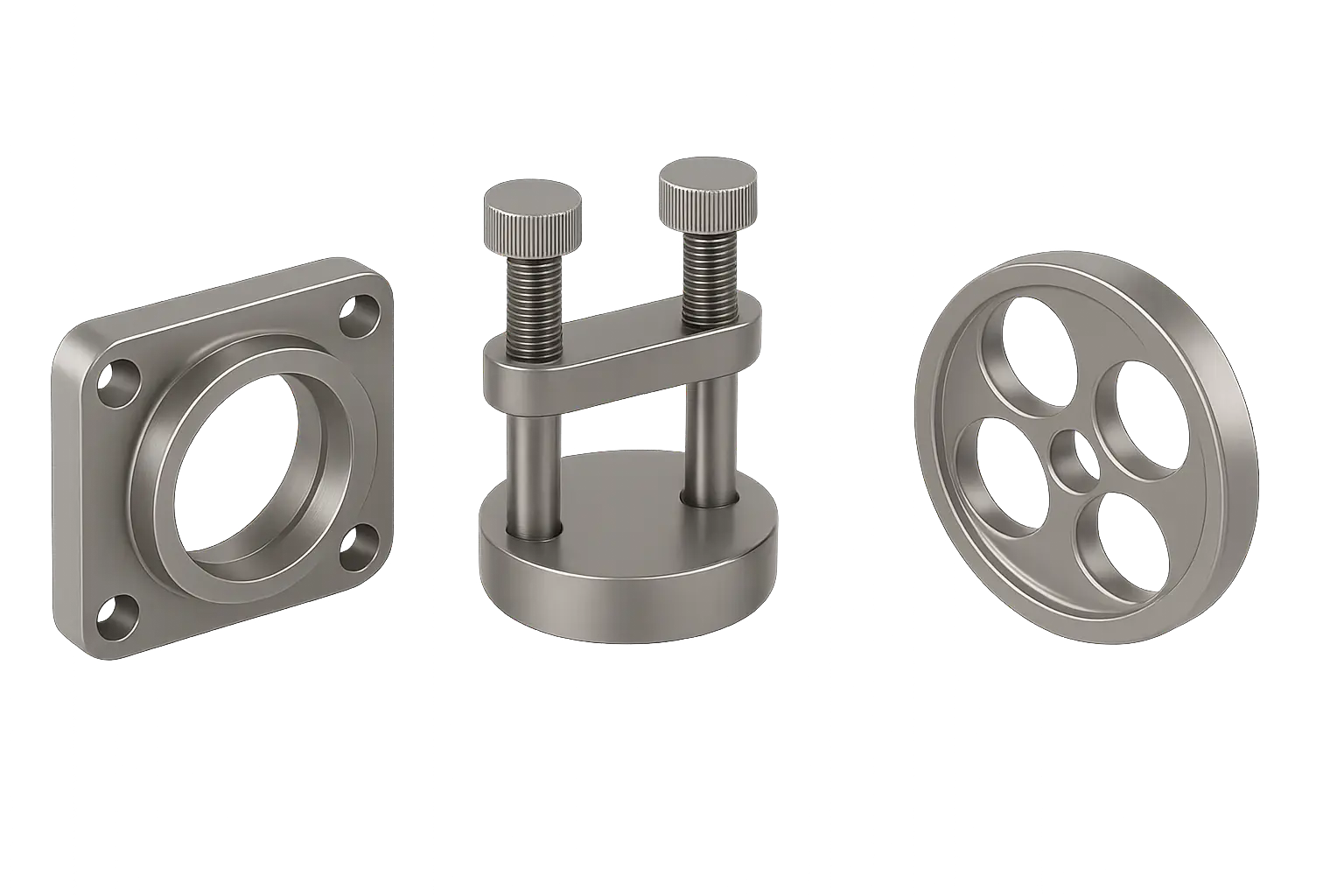

We're here to accelerate your path from prototype to production. Find our capabilities bellow.

Max Part Size

- Max Single Part Size:

- 850 × 700 × 500 mm ≈ 33 × 28 × 20 inch

- 500 kg ≈ 1100 lbs

- Max Toolmaking Project Size:

- 1000 × 1000 × 600 mm ≈ 39 × 39 × 24 inch

- 1000 kg ≈ 2200 lbs

Spindle Power & Speed Range

- 12 000 rpm – High Torque for Rough Machining

- 18 000 rpm – HSC for Fine Machining

- 60 000 rpm – Ultra Fine & Micro Machining

Precision Limits

-

Tolerances up to ±0.005 mm

-

Surface finish as fine as Ra < 0.05 µm

- Achievable under controlled thermal and vibration-isolated environments

Advanced Engineering Materials

- Superalloys: Inconel (718, 625)

- Hardened Tool Steels (up to 65 HRC)

- Stainless Steels: 304,314

- Titanium: Ti6Al4V

- Aluminium: 7075, 6061

- Soft Materials: Copper, Nylon, POM

-

Specials: Zerodur, 3D Metal Prints

Manufacturing Team

-

30+ years of CNC machining experience

- Master's degree engineers & up-to-date expertise:

- Desing and Engineering (CAD, DFM, FEA)

- Machining (CAM, Machine Inspection)

- Quality (GD&T, CMM, 3D Scanning, PPAP, FAI)

- Digitalisation (AI, ERP & MES, Robotics)

Trusted & Cost Effective Partner

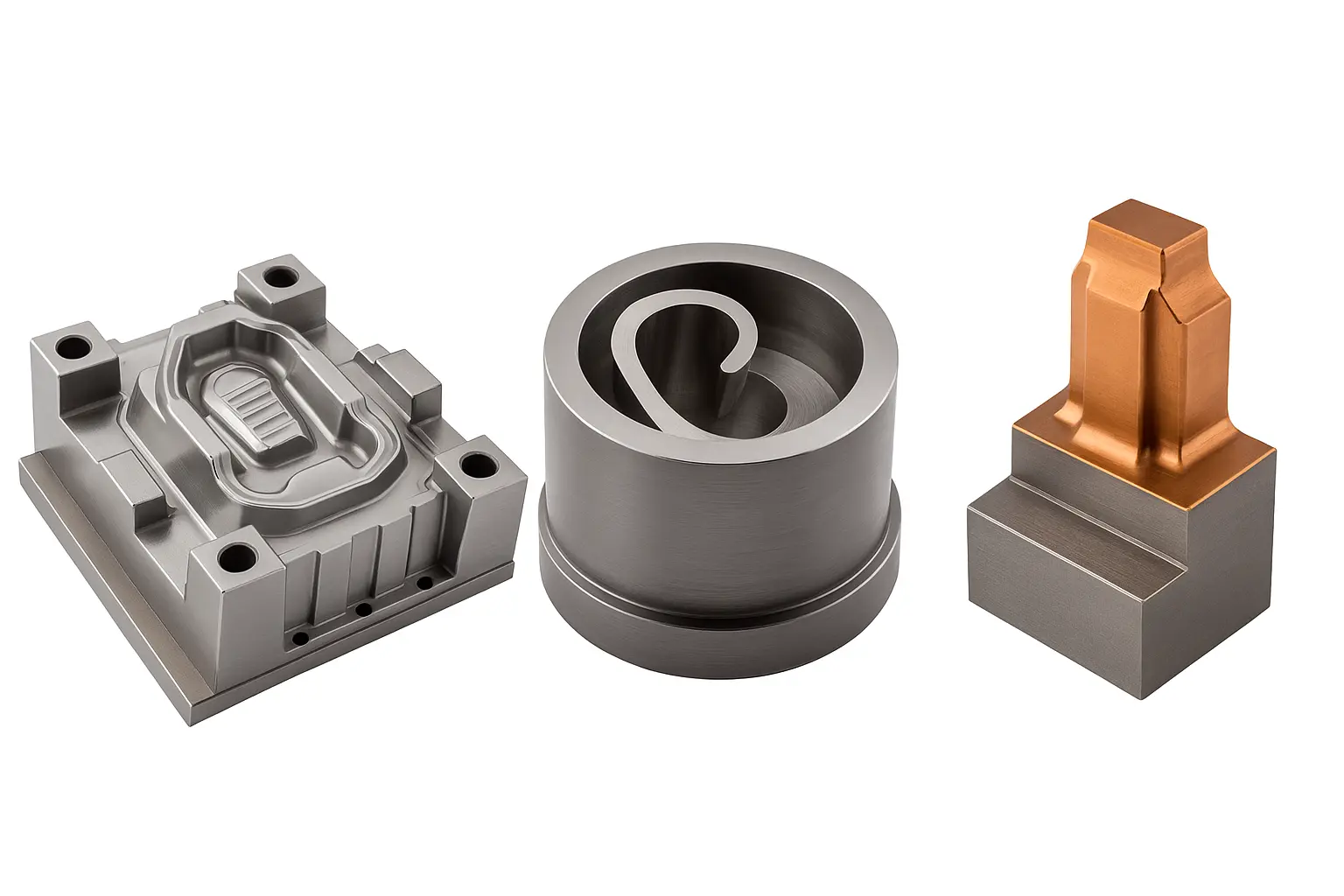

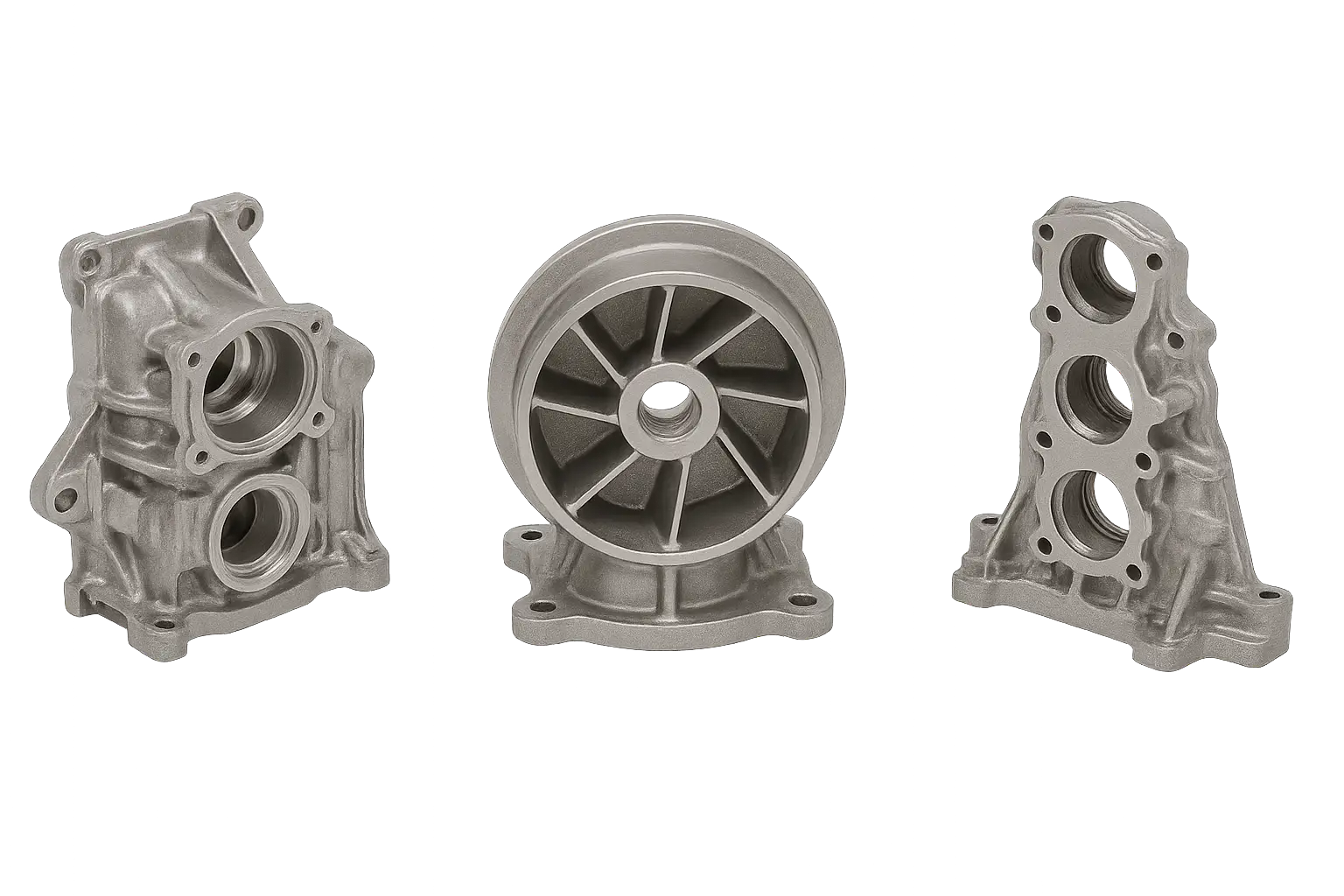

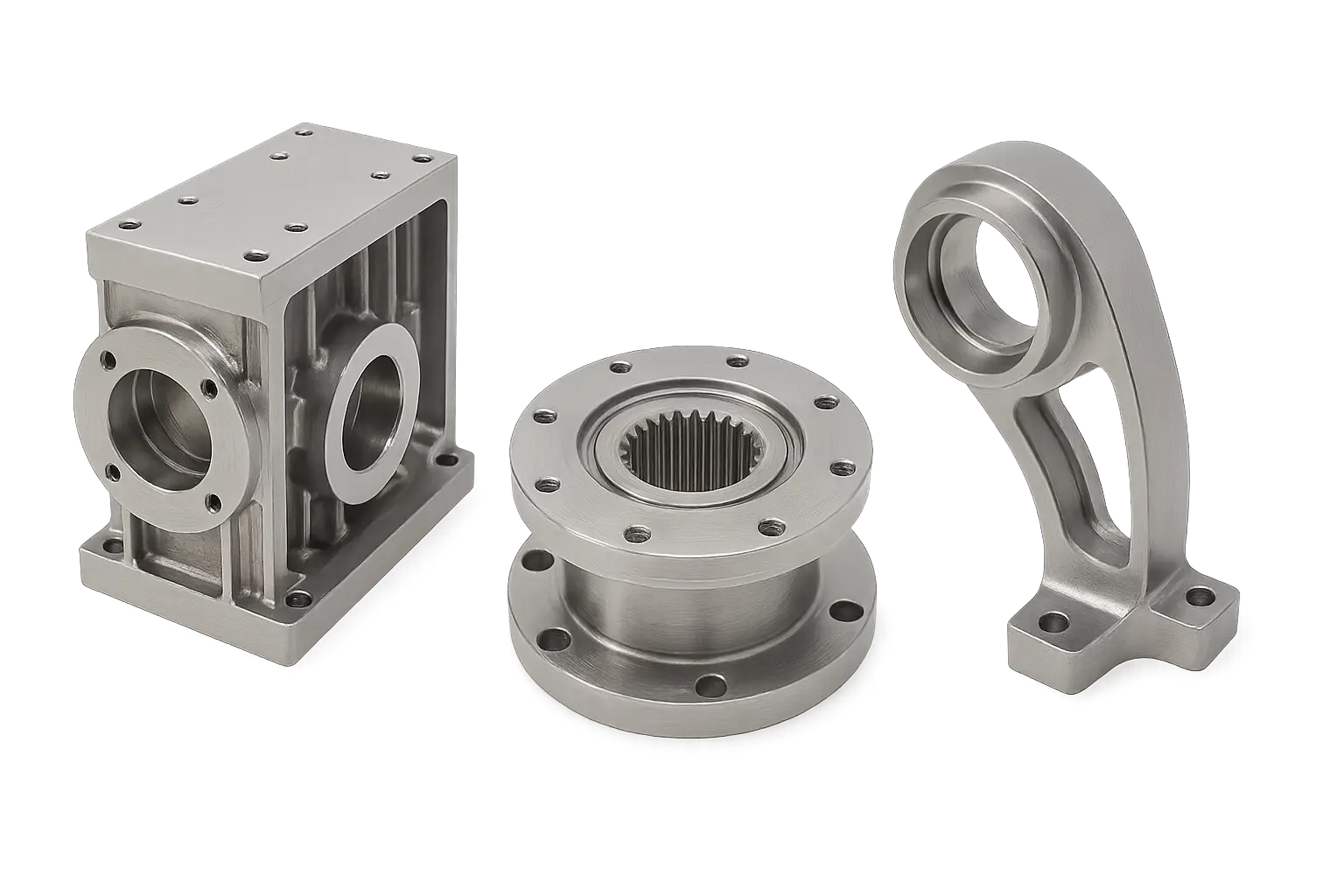

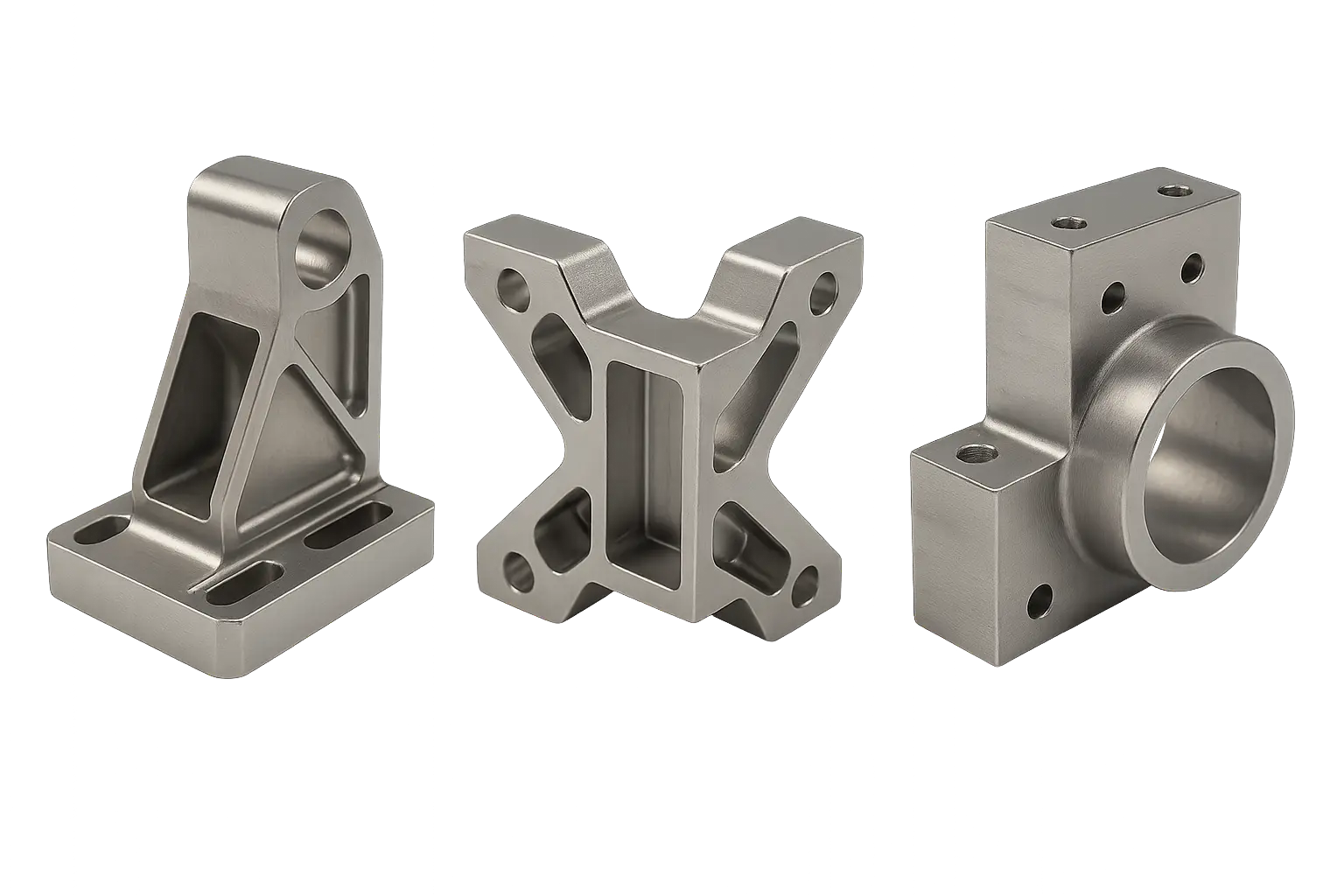

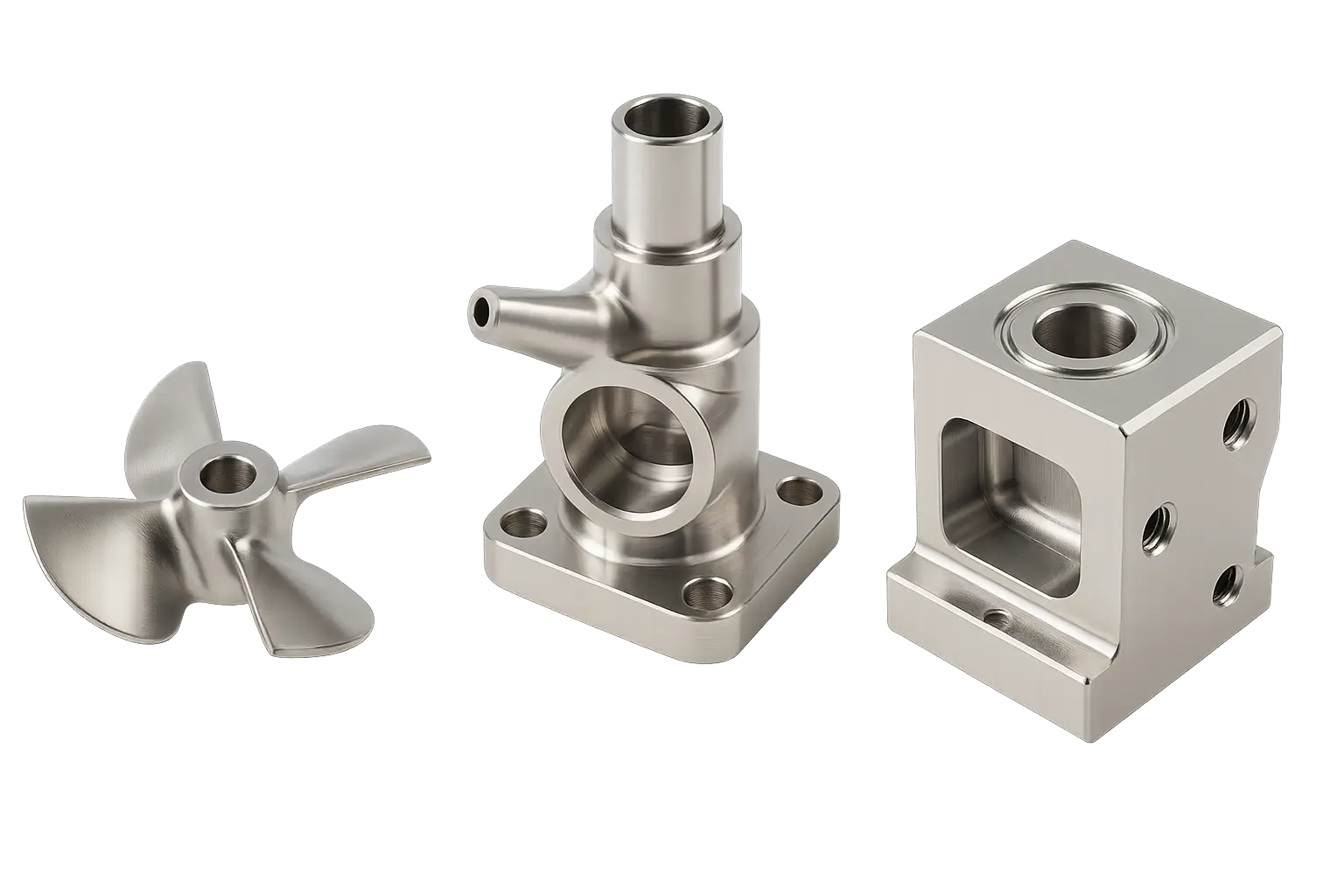

- Toolmaking, prototypes, serial parts production

- Lead times in days or weeks – not months

- Transparent pricing with no hidden costs

- Latest 5-axis strategies and cutting tools used

- Real-time updates, video progress calls available

- Flexible ramp-up programs for scaling production

- Highly adaptive to B2B supply chain systems

Searching for new CNC supply chain partner?

NPI - prototypes & toolmaking needed?

Chasing tight project deadlines?

Don't wait - Contact us Today!

🚀 High-Tech, Precision Industries

| Part Name | Description | Typical Materials |

|---|---|---|

| Injection Mold Core & Cavity | Highly contoured 3D surfaces for plastic molding (tools for production) | H13 tool steel, P20, 1.2343 ESR |

| Progressive Die Plates | Multi-stage forming tools for stamping sheet metal in high volumes | H11, D2, 1.2379, hardened steels |

| Forging Dies | Complex negative shapes for forming hot metal under pressure | H13, 1.2714, high-temperature steels |

| Die Casting Mold Inserts | Inserts for aluminum, zinc, or magnesium casting molds | H13, 1.2344, SKD61, |

| Electrode Holders for EDM | 3D-shaped copper/graphite parts for electrical discharge machining | Copper, Graphite, CuW alloys |

| Part Name | Description | Typical Materials |

|---|---|---|

| Turbine Blades (Blisks/IBRs) | Integrated airfoil components for jet engines or turbines | Titanium alloys (Ti-6Al-4V), Inconel |

| Structural Wing Ribs | Lightweight internal support components with pockets and weight-reduction cuts | Aluminum alloys (7075) |

| Aerospace Housings | Enclosures for sensors, gearboxes, actuators, or flight systems | Aluminum 6061/7075, Inconel, Titanium |

| Satellite Brackets & Frames | Lightweight but rigid components for supporting instruments in satellites | Aluminum 7075-T6, Titanium Grade 5 |

| Nozzle or Combustor Rings | High-temperature parts in engine combustion or propulsion systems | Inconel 718, Hastelloy, Titanium |

| Part Name | Description | Typical Materials |

|---|---|---|

| Jet Engine Mounts | Structural brackets that support engine loads and vibrations | Titanium alloys (Ti-6Al-4V), Inconel |

| Landing Gear Components | High-strength load-bearing parts with complex geometries | 300M steel, 4340 steel, Ti alloys |

| Avionics Chassis & Housings | Lightweight, high-precision enclosures for electronic flight systems | Aluminum 7075-T6, Magnesium alloys |

| Rotor Hub Assemblies | Central components connecting rotor blades in helicopters or tiltrotors | Titanium Grade 5, Maraging steel |

| Air Intake & Exhaust Components | Shaped for optimized airflow and heat resistance around jet engines | Inconel 718, Hastelloy, Ti-6Al-4V |

| Part Name | Description | Typical Materials |

|---|---|---|

| Watch Cases (Monobloc) | Intricately contoured and polished cases with complex internal profiles | 904L stainless steel, Grade 5 titanium, ceramic, gold alloys |

| Skeletonized Watch Bridges | Ultra-thin, lightweight components with intricate cutouts for high-end movements | Brass, titanium, rhodium-plated steel |

| Bezel Assemblies (engraved) | Precision bezels with tight tolerance grooves, gear profiles or gemstone seats | 316L, gold, platinum, ceramic |

| Crown & Pushers | Small, high-precision external control parts with sealing interfaces | Stainless steel, titanium, sapphire |

| Jewelry Settings (custom) | Sculpted mounts for diamonds or complex forms in luxury rings or pendants | Gold (18K), platinum, palladium |

| Part Name | Description | Typical Materials |

|---|---|---|

| Propeller Hubs | Central units connecting drone blades, requiring perfect balance and geometry | Aluminum 7075-T6, Titanium Grade 5 |

| Motor Mounts | Lightweight, rigid mounts with integrated cooling and thread features | Aluminum 6061-T6, Carbon Fiber Inserts |

| UAV Chassis Frame Nodes | Precision-milled joints for modular carbon/aluminum drone frames | Aluminum 7075-T6, Magnesium, CFRP blocks |

| Gimbal Mounts / Housings | Complex rotational frames for stabilized camera control | Magnesium alloys, Aluminum 6061-T6 |

| Battery Housing / Bay Shells | Lightweight, ventilated protective covers with mounting bosses | Plastic (machined POM), Aluminum 6061-T6 |

| Part Name | Description | Typical Materials |

|---|---|---|

| Hip Implants (Femoral Stem & Cup) | Complex contoured parts with organic geometries for human joints | Titanium Grade 5, CoCr alloys, Stainless Steel 316L |

| Spinal Fusion Cages | Interlocking, porous, often lattice-structured implants for vertebral support | PEEK, Titanium Grade 23 (ELI), CoCr alloys |

| Bone Plates & Trauma Fixation | Thin, contoured plates with multiple drilled holes for orthopedic use | Stainless Steel 316L, Titanium Grade 2/5 |

| Surgical Instruments (e.g. Forceps, Holders) | Highly precise tools with intricate gripping or clamping features | Stainless Steel 420/440, Titanium |

| Dental Abutments & Bars | Custom-angled connectors between implant and prosthetic crown | Titanium Grade 5, Zirconia, CoCr |

| Part Name | Description | Typical Materials |

|---|---|---|

| Custom Abutments | Patient-specific connectors between dental implants and prosthetic crowns | Titanium Grade 5, Zirconia |

| Implant Bars (All-on-4) | Precision-milled bars for full-arch restorations | Titanium Grade 5, Cobalt-Chrome (CoCr) |

| Monolithic Crowns & Bridges | Full-contour restorations milled from solid blocks | Zirconia, Lithium Disilicate, PMMA |

| Surgical Drill Guides | Guides used during implant surgery for accurate drilling | Medical Resin (PMMA), Titanium |

| Orthodontic Brackets/Bases | Custom base geometries for brackets or aligner attachments | Stainless Steel, Titanium |

| Part Name | Description | Typical Materials |

|---|---|---|

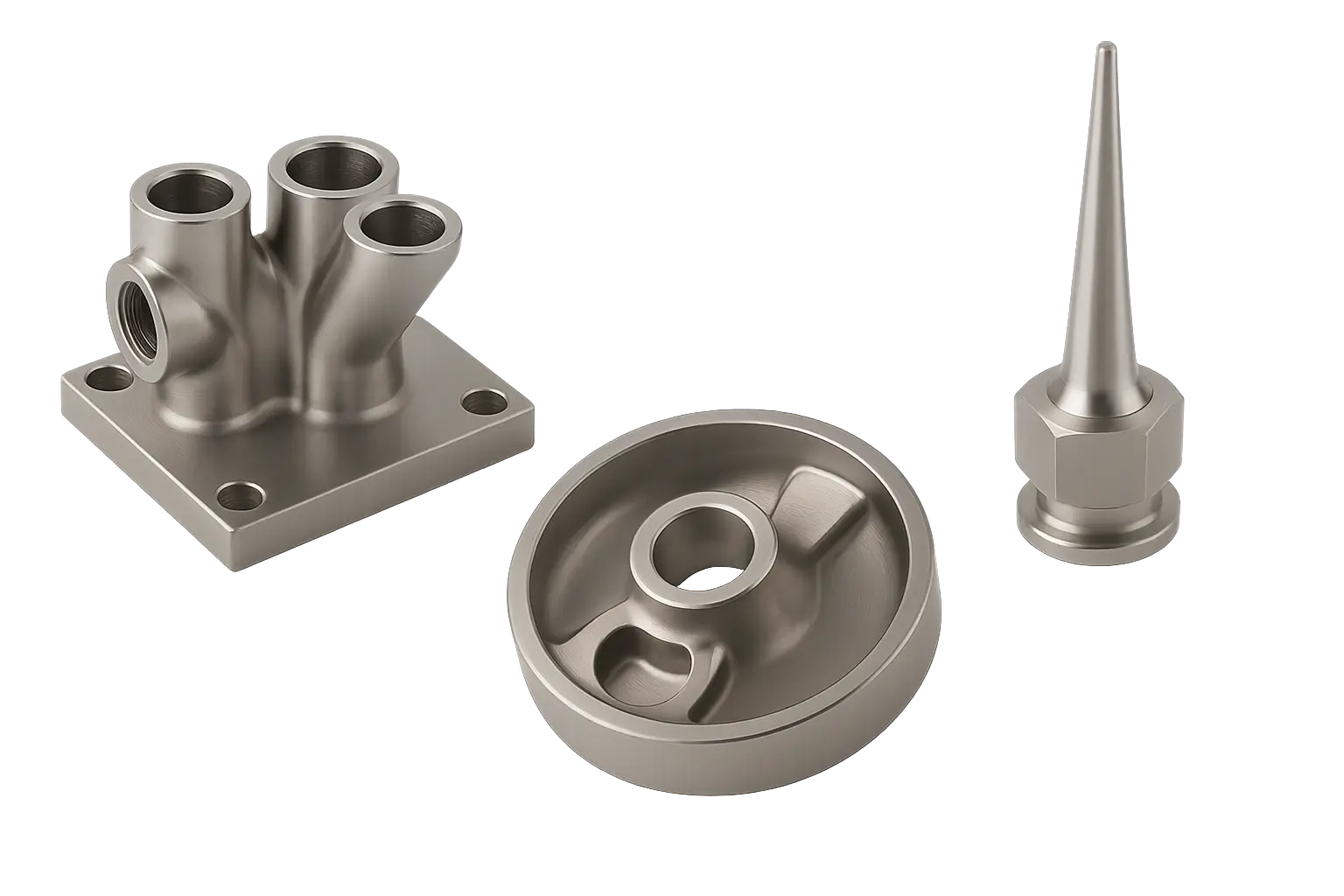

| Multi-Port Valve Bodies | Precision flow control components with internal channels and sealing surfaces | 316L Stainless Steel, Hastelloy C22 |

| Tablet Press Turret Plates | High-precision rotating plates with multiple punch stations | 316L Stainless Steel, Hard Chrome Coated |

| High-Shear Mixer Impellers | Complex-shaped blades for uniform mixing of active ingredients | 316L Stainless Steel, Duplex Stainless |

| Aseptic Filling Needles & Nozzles | Intricate, hygienic filling components requiring ultra-smooth surfaces | 316L Stainless Steel, Titanium Grade 2 |

| Custom Bioreactor Fittings | Complex, hygienic connectors for bioprocessing tanks and reactors | 316L Stainless Steel, PTFE-liner options |

| Part Name | Description | Typical Materials |

|---|---|---|

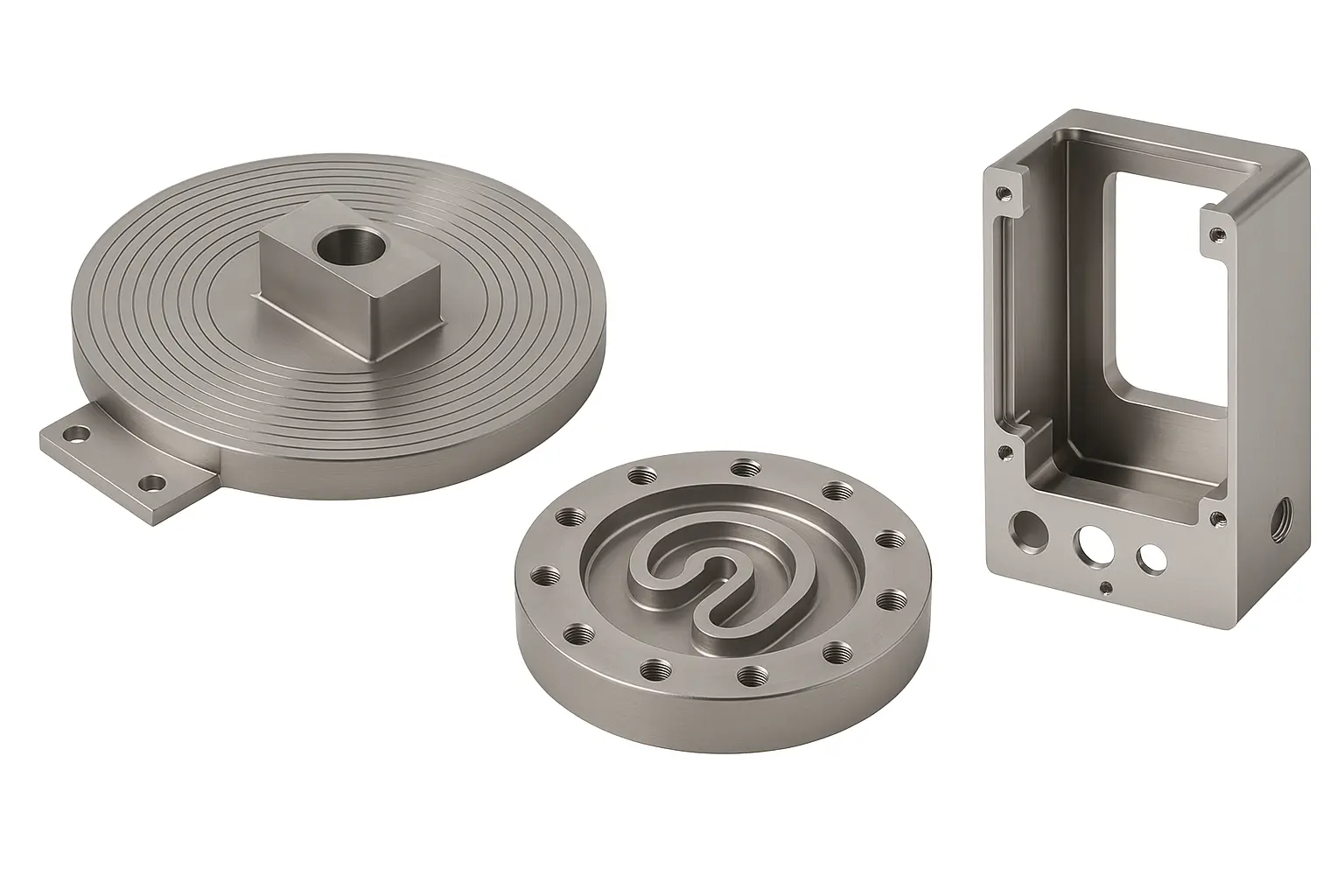

| Electrostatic Wafer Chucks | Precision vacuum or electrostatic clamping systems for wafers | Aluminum (hard anodized), Ceramic, Titanium |

| Chamber Liner Components | Internal parts for deposition or etching chambers, often chemically resistant | Aluminum 6061, 7075, Stainless Steel 316L, Hastelloy |

| Robot End Effectors | Intricate arms for picking and placing wafers within vacuum systems | Titanium, Aluminum, PEEK, CFRP |

| Gas Distribution Plates (Showerheads) | Evenly distribute process gases across wafers in PECVD/Etch tools | Aluminum (anodized), Quartz, Sapphire |

| Precision Cooling Plates | Micro-channel plates for liquid cooling in high-power or cleanroom systems | Copper, Stainless Steel, Aluminum alloys |

| Part Name | Description | Typical Materials |

|---|---|---|

| Optical Mirror Mounts | Precision-aligned adjustable fixtures for laser or optical mirrors | Aluminum 6061-T6, Stainless Steel 304/316 |

| Aspheric Lens Housings | Highly contoured geometries for holding custom optics in position | Aluminum, Titanium, Invar |

| Interferometer Baseplates | Flatness-critical, machined reference bases for metrology devices | Granite, Ceramic, Aluminum Tool Plate |

| Laser Beam Collimator Frames | Complex frames for aligning and focusing laser beams | Stainless Steel 316L, Invar, Copper Alloy |

| Precision XY Kinematic Stages | Multi-axis adjustable components for sub-micron positioning | Hardened Tool Steel, Aluminum, Brass |

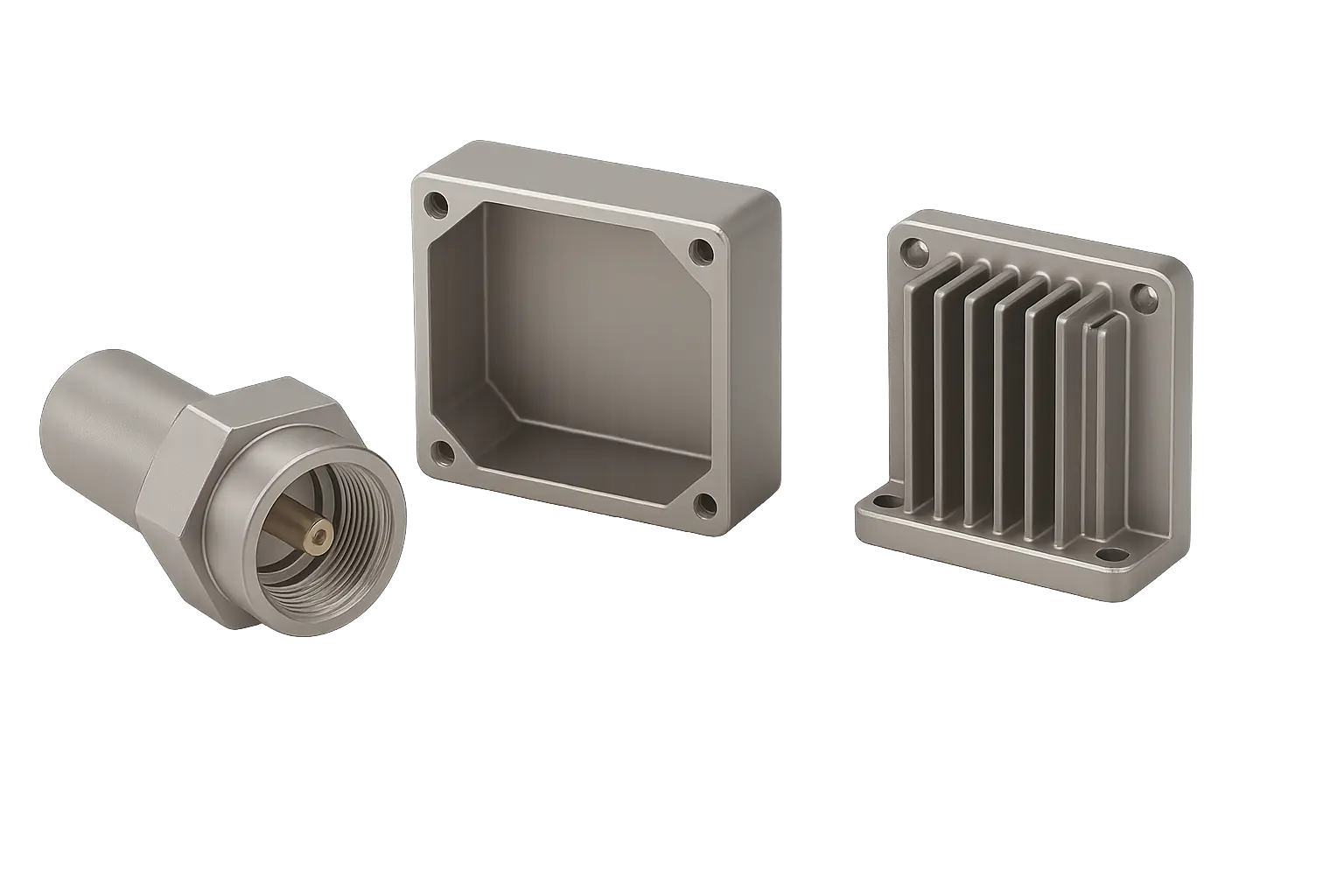

| Part Name | Description | Typical Materials |

|---|---|---|

| Waveguide Housings | Precision channels for directing high-frequency RF signals | Aluminum 6061-T6, Copper, Brass |

| RF Shielded Enclosures | Complex enclosures for EMI protection of sensitive electronics | Aluminum 5052/6061, Mu-metal, Stainless Steel |

| Antenna Array Mounting Frames | Lightweight but precise assemblies to align multi-element antennas | Aluminum 7075-T6, CFRP with metal inserts |

| Coaxial Connector Bodies | Small, high-tolerance components for RF signal transmission | Brass, Beryllium Copper, Stainless Steel |

| Heat-Sinking RF Backplates | Precision-milled plates for dissipating heat in RF amplifiers and power units | Copper, Aluminum with anodizing or plating |

🌀 Emerging & Advanced Manufacturing

| Part Name | Description | Typical Materials |

|---|---|---|

| Lattice-Structured Implants | Lightweight, porous medical parts for osseointegration | Titanium Grade 23 (ELI), CoCr alloys |

| Topology-Optimized Brackets | Aerospace or motorsport brackets with reduced weight and organic form | Ti-6Al-4V, AlSi10Mg, Inconel 718 |

| Conformal Cooling Injection Cores | Tooling inserts with internal curved channels for uniform cooling | 1.2709 Tool Steel, H13, Maraging Steel |

| Rocket Injector Nozzles | Internal passages with thin walls and high heat resistance | Inconel 718, Copper Alloy C18150, Hastelloy |

| Heat Exchanger Microstructures | Compact heat sinks with optimized surface area and fluid paths | Copper, Stainless Steel 316L, AlSi10Mg |

| Part Name | Description | Material |

|---|---|---|

| Aerospace Fuel Tank Dome Assembly | Hemispherical dome FSW-welded from panels; post-machined for sealing grooves, ports, and flange interfaces | Aluminium 2219 / 7075 |

| Rocket Intertank Panel | Flat stiffened panels joined by FSW; 5-axis machined for bolt holes and precision interfaces | Aluminium-Lithium Alloy |

| EV Battery Cooling Plate | Dual-plate heat exchanger with FSW internal channels; machined for inlets, outlets, and sealing surfaces | Aluminium 6061 / 3003 |

| Spacecraft Radiator Segment | Lightweight welded panels; 5-axis machined for manifolds, flat surfaces, and mounting features | Aluminium 6063 / 1050 |

| High-Speed Train Sidewall Frame | Structural frames FSW-welded from extrusions; precision-milled for doors, windows, and sensor interfaces | Aluminium 6005 / 6082 T6 |

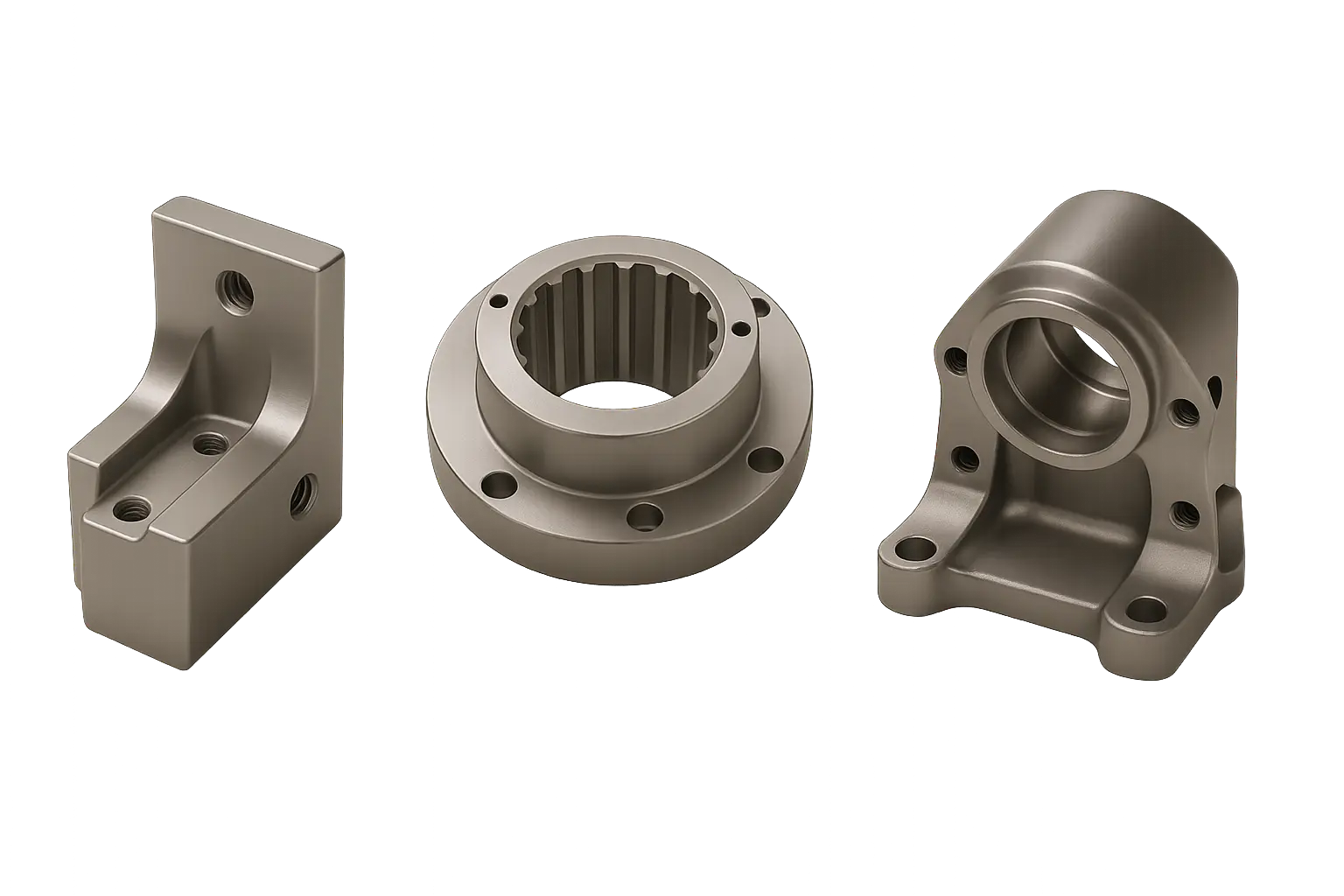

| Part Name | Description | Material |

|---|---|---|

| Robot Arm Base Bracket | Multi-axis mounting block with complex internal channels for cabling and servo connections | Aluminium 7075 / 6082 |

| End Effector Coupling Hub | Precision component for gripping tools or sensors; features spline fits, tapers, and internal bores | Stainless Steel 316 / 17-4PH |

| Harmonic Drive Housing | Thin-walled, high-precision part with gear interface surfaces and bearing seats | Aluminium 2024 / Titanium Ti6Al4V |

| Linear Rail Carriage Block | Compact carriage block with mounting holes, dowel pin bores, and guideway surfaces | Tool Steel 1.2379 / Hardened Steel 60+ HRC |

| Servo Motor Cooling Jacket | 3D milled aluminum housing with internal spiral coolant passages, sealing surfaces, and ports | Aluminium 6061 / Copper Alloy |

| Part Name | Description | Material |

|---|---|---|

| Sensor Integration Housing | Multilayer pocketed housing for embedded AI chips, sensors, and connectors; high thermal and EM control | Aluminium 6061-T6 / Copper Alloy |

| Adaptive Motor Mount Block | Complex, weight-optimized mount with internal coolant routing and precision mating surfaces | Aluminium 7075 / Titanium Ti6Al4V |

| AI-Controlled Actuator Bracket | Multi-axis linkage part for smart actuators with sensor mounts and internal wiring channels | Stainless Steel 316 / PEEK (hybrid) |

| Smart Vision System Frame | Lightweight frame with integrated camera/sensor holders and cooling slots for AI-based visual control | Aluminium 2024 / Carbon-Reinforced Polymer |

| Micro-Servo Heat Sink Baseplate | Compact, fin-structured cooling plate for embedded mechatronic AI modules | Aluminium 1050 / 6063 |

| Part Name | Description | Material |

|---|---|---|

| Optical Microscope Base Frame | Rigid frame with vibration-damping features, precisely machined for lens alignment and stability | Aluminium 6061-T6 / Granite-Alu Hybrid |

| Mass Spectrometer Ion Trap Housing | Intricate chamber with ultra-tight tolerances and electrode mounting interfaces | Titanium Grade 2 / Stainless Steel 316L |

| Precision Sample Stage Carrier | Multiaxis rotating platform for nanometer-level positioning; machined with micro-grooves and cavities | Aluminium 7075 / Invar Alloy |

| Fluidic Control Manifold Block | Multi-channel fluid block for microfluidic systems; requires deep pocketing, sealing, and port accuracy | PEEK / PTFE / Stainless Steel 304 |

| Cryogenic Sample Holder | Thermally isolated, pocketed structure for holding specimens at low temperatures during testing | Oxygen-Free Copper / Stainless Steel 304L |

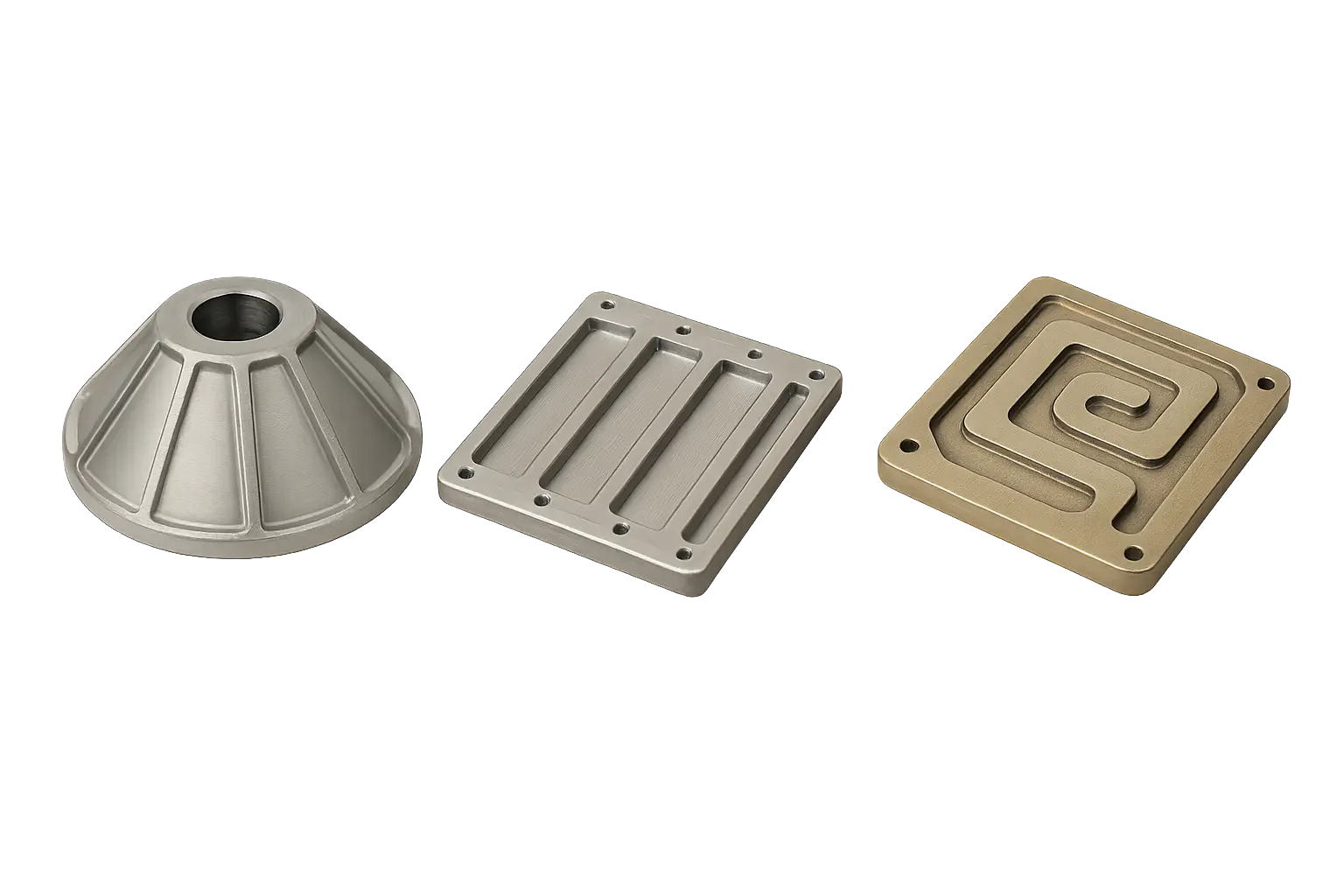

| Part Name | Description | Material |

|---|---|---|

| IoT Device Aluminum Enclosure | Compact multi-surface case for sensors and processors; precision-milled with integrated heat fins and mounting slots | Aluminium 6061-T6 / 7075 |

| RF Shielded Connector Housing | Complex shell with tight-fit cavities for electromagnetic shielding of high-frequency components | Copper Alloy / Brass |

| PCB Mounting Baseplate | Thin, pocketed platform with standoff bosses and fine-thread holes for board alignment and grounding | Aluminium 5052 / Stainless Steel 304 |

| Smart Sensor Gimbal Bracket | Multi-axis rotational frame for camera or sensor modules, machined with fine bearings and wiring channels | Titanium Ti6Al4V / Aluminium 7075 |

| Miniature Heat Sink Assembly | Finned heat dispersion module with high-density surface features for compact microcontrollers | Aluminium 1050 / Copper |

| Part Name | Description | Typical Materials |

|---|---|---|

| Actuator Arm Linkage | Multi-axis jointed component that transfers force from motor to limb segments | Titanium Grade 5, 7075-T6 Aluminum |

| Ergonomic Spine Frame | Anatomically contoured backbone support structure for load-bearing exosuits | Carbon Fiber-Aluminum Hybrid, 6061-T6 |

| Jointed Knee Pivot Hub | Precision rotary interface allowing multi-directional leg motion | 17-4PH Stainless Steel, Ti-6Al-4V |

| Forearm Servo Housing | Compact protective shell for embedded servo motors with cable routing features | 7075-T6 Aluminum, Magnesium Alloy |

| Wearable Neural Connector Base | Base plate with intricate pockets for sensor and neural feedback integration | Titanium Grade 23 (ELI), PEEK-Ti hybrid |

| Part Name | Description | Material |

|---|---|---|

| Neural Probe Array Housing | Ultra-compact frame to hold flexible electrode arrays; features precision pockets and insulation gaps | Titanium Grade 2 / PEEK |

| Skull-Mounted BCI Implant Shell | Biocompatible protective casing with undercuts and port flanges for signal/data connectors | Titanium Ti6Al4V / PEEK |

| Signal Amplifier Cooling Block | Precision-milled heat sink with integrated micro-channels for embedded amplifier cooling | Aluminium 6063 / Copper |

| Cranial Fixation Baseplate | Contoured plate with countersunk screw seats and precision tapers to fit skull curvature | Titanium Grade 5 / Stainless Steel 316L |

| Neurointerface Dock Connector Frame | Complex geometry part that secures signal/data transmission modules with aligned guide pins and EMI shields | Aluminium 7075 / Conductive Polymer |

⚡ Power Generation & Energy Infrastructure

| Part Name | Description | Typical Materials |

|---|---|---|

| Control Rod Drive Mechanism (CRDM) Housing | Precision-machined cylindrical assembly with tight tolerances for linear actuation of neutron-absorbing rods. | Inconel 718, 316L Stainless Steel |

| Steam Generator Tube Sheet Block | Thick plate with hundreds of angled holes requiring multi-axis drilling and surfacing for tube alignment. | Inconel 600, Duplex Stainless Steel |

| Reactor Core Support Grid Segment | Intricately machined lattice frame with intersecting channels for guiding fuel rod bundles. | Zircaloy-4, 316 Stainless Steel |

| Primary Coolant Pump Impeller | Complex curved impeller with optimized flow blades for high-pressure coolant circulation. | Monel K500, Inconel 625 |

| Sealed Valve Actuator Cover | Multi-surface precision housing with flange grooves, bolt patterns, and sealing pockets. | 17-4PH Stainless Steel, Titanium Grade 2 |

| Part Name | Description | Typical Materials |

|---|---|---|

| Main Shaft Bearing Housing | Large, precision-machined housing with concentric bores, flange mounts, and deep pocket geometry. | Cast Steel, 42CrMo4, Nodular Cast Iron (EN-GJS-400) |

| Rotor Hub Mount Interface | Complex multi-face component connecting blades to the hub, requiring perfect angular tolerances. | High-Strength Steel, GGG-60 |

| Pitch Control Gear Segment | Curved gear sector with mounting holes and tight backlash tolerance for blade angle adjustment. | Nitrided Steel, Case-Hardened 18CrNiMo7-6 |

| Yaw Drive Planet Carrier | Intricate multi-axis carrier body holding planetary gears with internal cutouts and splines. | Alloy Steel 34CrNiMo6, Surface-Treated Steel |

| Generator Cooling Manifold Block | Multi-port coolant block with intersecting channels and threaded inlets/outlets, precision-sealed. | Aluminum 7075-T6, Stainless Steel 316L |

| Part Name | Description | Typical Materials |

|---|---|---|

| Battery Module End Plate | Precision-machined compression plate to secure pouch or prismatic cells, with integrated cooling and cable slots. | Aluminum 6061-T6, CFRP Inserts |

| Busbar Distribution Block | Multi-terminal current-carrying structure with deep milling and tight flatness tolerance for power flow. | Copper C110, Nickel-Plated Aluminum |

| Thermal Management Baseplate | 3D-contoured base with integrated cooling channels and flatness-critical zones for cell contact. | Aluminum 6082, Liquid-Cooled Aluminum 7075 |

| High-Voltage Connector Housing | Multi-axis housing with internal partitions, O-ring grooves, and dielectric isolation zones. | Glass-Filled PEEK, Insulating Polymer-Aluminum Hybrid |

| Battery Pack Structural Frame Lug | Complex lug with ribbing, bolt seats, and multi-angle chamfers to integrate into pack casing. | Aluminum 5083, Steel S355 |

| Part Name | Description | Typical Materials |

|---|---|---|

| Solar Tracker Drive Bracket | Multi-angled bracket with reinforced ribbing, bolt pockets, and motor mount surfaces for solar panel rotation. | Aluminum 6082-T6, Steel S355 |

| Heliostat Arm Yoke Joint | Precision contoured yoke with pin bores and offset flanges for adjustable mirror alignment. | Stainless Steel 304, Aluminum 7075 |

| Inverter Heat Sink Baseplate | Machined base with micro-fin channels and flatness-critical surface for thermal transfer. | Aluminum 6061, Anodized Copper Inserts |

| Structural Mounting Node | Complex joint block linking angled solar frame arms with tapped holes and hidden cable paths. | Aluminum 6063-T6, Carbon Steel |

| High-Efficiency Lens Frame Adapter | Precision multi-contour frame for Fresnel lens or solar concentrator modules. | CNC-Grade Acrylic, Machined Aluminum |

| Part Name | Description | Typical Materials |

|---|---|---|

| Francis Turbine Runner Blade | Intricate curved blade with 3D fluid-optimized geometry requiring simultaneous multi-axis contouring. | Stainless Steel 13Cr-4Ni, Duplex Steel |

| Pelton Bucket Segment | Deep pocketed and highly contoured cup structure milled from solid for high-pressure jet impact. | Stainless Steel 304, Inconel 718 |

| Guide Vane Segment | Precision-machined pivoted vane with circular ends and cambered profile to regulate water flow. | Stainless Steel 316L, Martensitic Stainless Steel |

| Turbine Shaft Coupling Flange | Large multi-face flange with concentric bores, bolt circles, and spline fitting. | Forged Steel 42CrMo4, Cast Steel |

| Spiral Casing Insert Plate | Multi-axis milled internal flow plate with spiral curve for controlling inlet velocity profile. | Cast Stainless Steel, Bronze-Ni-Al Alloy |

| Part Name | Description | Typical Materials |

|---|---|---|

| Turbine Blade (Airfoil) | Complex twisted blade with cooling holes, fir-tree root, and shroud — requires simultaneous 5-axis contouring. | Inconel 718, Rene 41, Titanium Alloy |

| Nozzle Guide Vane Segment | Precision-machined vanes with airfoil shapes, cooling channels, and mounting lugs. | Hastelloy X, Inconel 738 |

| Combustor Liner Dome | Deep-formed dome with multi-hole arrays and thermal barrier coating interfaces. | Haynes 230, Inconel 625 |

| Swirler Assembly Body | Multi-ported cylindrical component that shapes fuel-air flow into the combustor. | Stainless Steel 316L, Hastelloy X |

| Casing Coupling Flange | Large ring-shaped flange with multi-hole patterns, tapered faces, and radial cutouts for thermal stress relief. | Steel 42CrMo4, Nickel-Alloyed Steel |

| Part Name | Description | Typical Materials |

|---|---|---|

| Subsea Valve Block (Manifold) | Large multi-port block with intersecting internal channels, sealing grooves, and precision-tapped ports. | Inconel 625, Duplex Stainless Steel |

| Drill Bit Nozzle Core | Compact, high-wear insert with angular flow paths and erosion-resistant surfaces. | Tungsten Carbide, Stainless Steel 17-4PH |

| Blowout Preventer (BOP) Housing Segment | Thick-walled multi-axis machined part with complex sealing and bolt interfaces. | AISI 4130, Clad Inconel |

| Mud Motor Transmission Coupling | Cylindrical component with splines, helical fluting, and cross-drilled lubrication ports. | 4145H Steel, Nitrided 4340 |

| Wellhead Adapter Flange | Multi-bolt circular flange with stepped sealing surfaces, boreholes, and multi-face milling. | AISI 8630, Nickel-Plated Steel |

⚙️Industrial & Engineering Sectors

| Part Name | Description | Typical Materials |

|---|---|---|

| Cylinder Head Prototype | Complex multi-face geometry with combustion chamber shaping, valve seats, and coolant channels. | Aluminum 6082 / A356, Cast Iron |

| Turbocharger Impeller | Freeform blade geometry requiring precise multi-axis machining for performance and balance. | Inconel 718, Titanium Grade 5 |

| Suspension Control Arm (Prototype) | Lightweight part with complex contours and multi-angled machined pockets. | Aluminum 7075-T6, Steel 42CrMo4 |

| EV Battery Tray Cooling Plate | Milled 3D fluid channels and sealing grooves on large, flat heat exchanger base. | Aluminum 6061-T6, Copper Alloy |

| Gearbox Casing (Motorcycle / Racing) | Multi-surface transmission housing with bearing bores, ribs, and alignment points. | Aluminum A319, Magnesium Alloy |

| Part Name | Description | Typical Materials |

|---|---|---|

| Controllable Pitch Propeller Blade | Complex hydrofoil geometry requiring precise camber and twist angles, optimized for propulsion efficiency. | Nickel-Aluminum Bronze, Stainless Steel 316L |

| Rudder Hinge Yoke Assembly | Multi-face machined yoke with tight alignment bores for rudder actuation systems. | Duplex Stainless Steel, 42CrMo4 Steel |

| Stern Tube Bearing Housing | Deep-pocket housing with oil grooves and concentric bore for shaft alignment in propulsion system. | Cast Steel, Stainless Steel 304 |

| Wave-Piercing Bow Fairing Segment | Freeform surface panel with undercuts and recessed reinforcement pockets for high-speed marine craft. | Aluminum 5083-H321, CFRP-Aluminum Hybrid |

| Subsea Manifold Valve Block | 5-axis machined block with intersecting high-pressure fluid passages and threaded ports. | Inconel 625, Super Duplex (2507) |

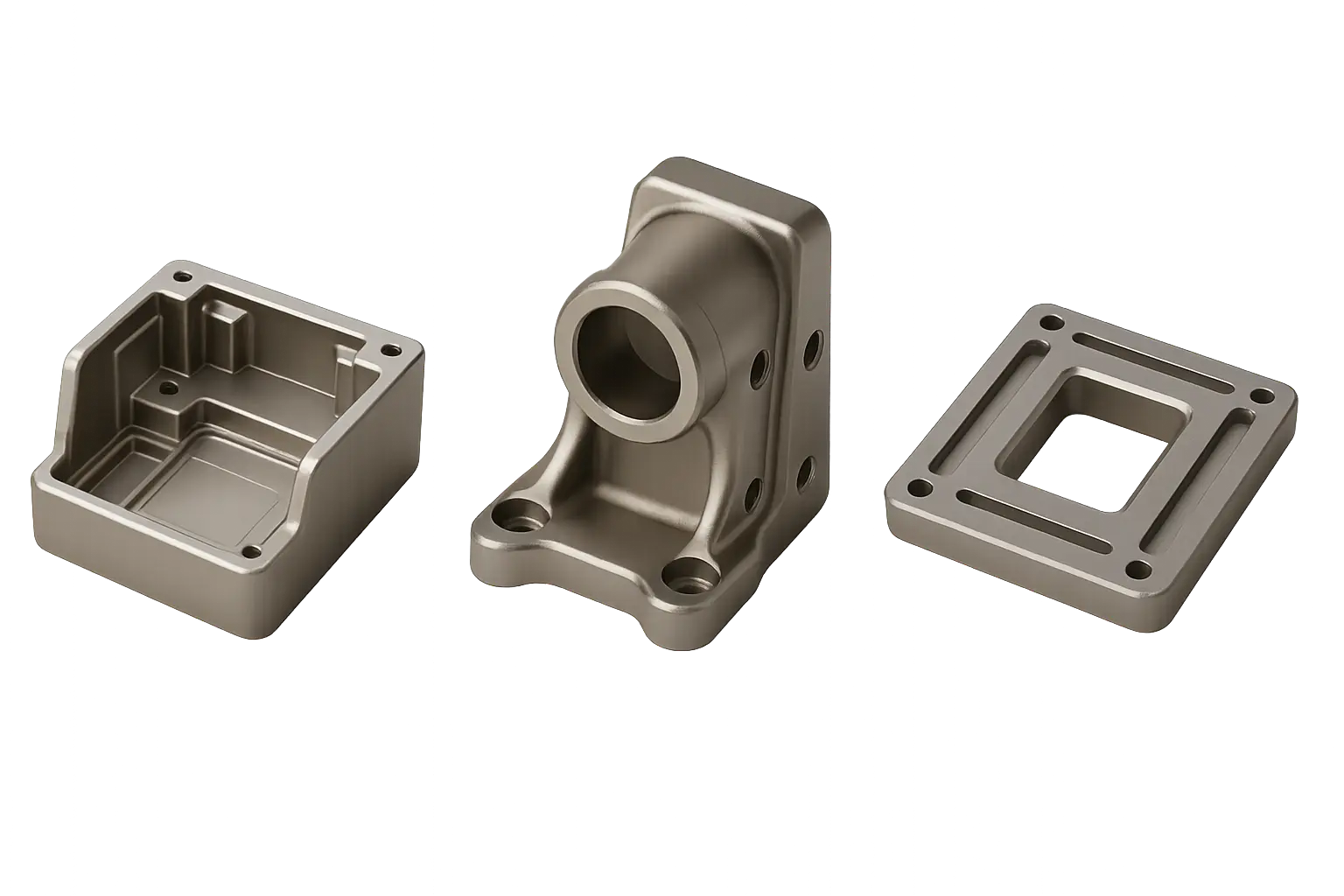

| Part Name | Description | Material |

|---|---|---|

| Hydraulic Valve Body Block | Precision-milled block with intersecting internal oil channels, threaded ports, and flat sealing faces | Steel 42CrMo4 / Stainless Steel 316 |

| Rotary Pneumatic Actuator Housing | Cylindrical housing with spiral grooves and internal vanes, requiring multi-axis undercuts | Aluminium 7075 / Cast Iron |

| Manifold Mounting Base | Multi-port fluid distribution base with high-accuracy hole alignment and O-ring grooves | Aluminium 6061 / Brass |

| Hydraulic Cylinder End Cap | Complex cap with integrated threads, pressure relief features, and fine groove paths for seals | Steel 1.1191 / Stainless Steel 304 |

| Servo-Valve Pilot Plate | Thin plate with precision orifices and micro-milled oil control channels for pilot signal regulation | Inconel 718 / Titanium Grade 5 |

| Part Name | Description | Material |

|---|---|---|

| Multi-Axis Rotary Fixture Body | Core rotating base with internal cooling paths, dowel pin bores, and angular faces for servo interface | Aluminium 7075 / Stainless Steel 420 |

| Cam-Driven Slide Block | Precision curved guide with varying surface paths for cam-follower operation under high cycle rates | Tool Steel 1.2343 / Hardened 60+ HRC |

| High-Speed Spindle Nose Cone | Aerodynamic conical part with concentric bearing seats and dynamically balanced form | Titanium Ti6Al4V / Aluminium 2024 |

| Custom Valve Manifold Base | Multi-port fluid control block with intersecting milled channels and threaded sensor ports | Stainless Steel 316L / Brass |

| Machine Frame Joint Node | Structural connector block with complex angled planes and pocketed areas for bolt and alignment pins | Aluminium 6082 T6 / Mild Steel |

| Part Name | Description | Material |

|---|---|---|

| Turbine Blade Root Repair Insert | Complex dovetail-shaped insert welded into damaged turbine blades, requiring 5-axis re-contouring | Inconel 718 / Hastelloy |

| Mold Tool Surface Rebuild Block | Custom-fit block for damaged mold cavities, precision machined to match freeform geometries | H13 Tool Steel / 1.2343 |

| Weld Overlay Pump Shaft Section | Cladded shaft region machined post-weld for bearing fits and concentricity | Stainless Steel 316 / Duplex |

| Cracked Gear Hub Reinforcement | Reinforcement cap for cracked gear centers, 5-axis machined to match spline and hub features | 42CrMo4 / EN24 Steel |

| Damaged Casing Flange Re-machining | Weld-repaired flange area machined to original sealing and bolt pattern specs | Cast Iron / Aluminium 6082 |

| Part Name | Description | Material |

|---|---|---|

| Nozzle Swirl Chamber Core | Internal swirl-generating core for high-pressure fire suppression nozzles with tight flow path geometry | Stainless Steel 316L / Brass |

| Thermal Sensor Housing | Precision-milled enclosure for thermal trigger sensors with complex sealing geometry and mounting flanges | Aluminium 6061 / Copper Alloy |

| Flame Retardant Valve Block | Multi-port control block for automatic extinguisher systems, with micro-channel fluid routing and thread alignment | Brass / Stainless Steel 304 |

| Pressure Relief Disc Retainer | Dome-shaped machined cap with integrated burst scoring and safety lip design | Inconel 625 / Aluminium 7075 |

| Sprinkler Head Adjustment Hub | Multi-axis hub with elliptical cutouts and sliding lock features for field-adjustable ceiling systems | Aluminium 2024 / PEEK (heat-resistant) |

| Part Name | Description | Material |

|---|---|---|

| Helical Heat Exchanger Core | Compact spiral-channeled core with variable pitch for efficient heat transfer | Copper Alloy / Inconel 625 |

| Multi-Stage Compressor Impeller | Precision impeller with backward-curved vanes and tight hub tolerances | Titanium Grade 5 / Aluminium 7075 |

| Variable Geometry Valve Body | Asymmetric valve block with multiple flow pathways and actuator integration | Stainless Steel 316L / Brass |

| Thermal Regulation Manifold | Complex internal routing for liquid/gas distribution, includes sensor ports | Aluminium 6061-T6 / PEEK |

| Condenser Micro-Fin Plate | Thin-profile component with 3D micro-fin structures for high surface exchange | Copper / Aluminium 1050 |

| Part Name | Description | Material |

|---|---|---|

| Turbine Blade Root Finishing | Precision-machined root features for forged turbine blades with tight tolerances | Inconel 718 / Titanium Grade 5 |

| Crankshaft Oil Channel Router | Multi-axis drilling and internal routing for forged crankshafts with complex geometry | 42CrMo4 / AISI 4340 Steel |

| Landing Gear Clevis Block | Forged structural component with undercuts, compound angles, and bearing seats | 300M Alloy Steel / 7075-T6 Aluminium |

| Connecting Rod Cap Seat | High-precision seat surfacing and alignment holes for forged connecting rods | EN24T / AISI 4140 |

| Forged Yoke Housing | Asymmetrical housing with tight bores, splines, and intersecting axes | 17-4PH Stainless Steel / EN36 |

| Part Name | Description | Typical Materials |

|---|---|---|

| Turbine Blade Segment | Post-cast precision machining of complex aerofoil profiles, including fir-tree roots and shrouds. | Inconel 718, Titanium Grade 5 |

| Orthopedic Femoral Component | Final finishing of cast medical implants with smooth surfaces and precise curvature. | Cobalt-Chrome Alloy, Stainless Steel 316L |

| Fuel Injector Body | Precision-drilled microchannels and seating surfaces after casting for high-pressure fuel systems. | Stainless Steel 17-4PH, Inconel 625 |

| Valve Housing with Internal Cavities | 5-axis machining of intricate internal passages and flange faces after investment casting. | Duplex Stainless Steel, Hastelloy |

| Impeller Core with Curved Blades | Precision contouring of blades and hub geometry post-casting, requiring simultaneous multi-axis toolpaths. | Aluminum Bronze, Inconel 713C |

| Part Name | Description | Typical Materials |

|---|---|---|

| Transmission Housing (Multi-Cavity) | Post-machining of mating surfaces, bearing seats, and complex internal geometries with deep pocketing. | Aluminum A380, Magnesium AZ91D |

| Automotive Cylinder Head | Machining of cooling channels, valve seats, and spark plug bores after casting. | Aluminum A356, AlSi10Mg |

| High-Performance Heat Sink Core | Precision contouring of thin fins and mounting interfaces for electronic cooling modules. | Aluminum ADC12, AlSi9Cu3 |

| Electric Motor Stator Housing | Multi-surface machining including bores, flange faces, and ribbed sections with alignment tolerances. | Aluminum A360, Magnesium AE42 |

| Complex Gearbox Casing | 5-axis trimming of cast surfaces, bearing cavities, and tight-tolerance alignment features. | Aluminum A319, Zinc Zamak 5 |

| Part Name | Description | Typical Materials |

|---|---|---|

| Engine Block V-Type (V6/V8) | Post-casting machining of bore alignment, deck surfaces, and oil passages with tight tolerances. | Cast Iron (GJL-250), Aluminum A356 |

| Marine Propeller Hub | Finishing of multi-angled curved blade roots and central bore for marine propulsion systems. | Bronze (CuSn10), Nickel-Aluminum Bronze |

| Heavy-Duty Hydraulic Manifold | 5-axis contouring and port machining on large cast blocks with internal fluid paths. | Ductile Iron (GJS-400), Steel GS-C25 |

| Compressor Casing (Split Shell) | Precision surfacing and internal cavity finishing on large turbomachinery casings. | Cast Steel, Aluminum A319 |

| Industrial Pump Housing | Multi-face machining of mounting flanges, threaded ports, and concentric bores. | Cast Iron, Stainless Steel CF8M |

| Part Name | Description | Typical Materials |

|---|---|---|

| Multi-Axis Trunnion Bracket | Angular mounting bracket for rotating assemblies, often with compound angles and gusseted reinforcements. | Aluminum 7075-T6, Stainless Steel 304 |

| Aerospace Bulkhead Support Lug | Precision-machined bracket for load transfer in airframes, with tight tolerances on curved contact surfaces. | Titanium Grade 5, Aluminum 7050 |

| Engine Mount Arm with Ribbing | Cast or billet machined bracket with weight-optimized ribbed structure and multi-plane mounting faces. | Aluminum A356, Cast Steel |

| Heavy-Duty Equipment Mount | 5-axis profiled bracket with integrated shock absorption zones and precision bores. | High-Strength Low-Alloy (HSLA) Steel, Inconel 718 |

| Curved Reinforcement Node | Intersecting node for tubular or composite structures, often used in exoskeletons or robotic frameworks. | Stainless Steel 316L, Aluminum 6061 |

| Part Name | Description | Typical Materials |

|---|---|---|

| Linear Actuator Housing Block | Precision-machined enclosure for ball screw or belt-driven actuators with multiple bearing seats and guideways. | Aluminum 7075, Stainless Steel 304 |

| Rotary Servo Motor Mounting Frame | Multi-face housing that aligns stator, rotor, and encoder assembly with exact center offset tolerances. | Aluminum 6061-T6, Cast Iron |

| Precision Worm Gear Carrier | Complex carrier supporting angular gear systems in servo-assisted motion platforms. | Steel 42CrMo4, Bronze Alloy |

| Robotic Arm Joint Segment | 5-axis contoured segment with integrated cable routing channels and bearing pockets. | Titanium Grade 5, Aluminum 7050 |

| Encoder Disc Hub Assembly | Ultra-precise rotating element with optical pattern surfaces and exact alignment for closed-loop control. | Stainless Steel 316L, Invar |

| Part Name | Description | Typical Materials |

|---|---|---|

| Linear Actuator Housing Block | Precision-machined enclosure for ball screw or belt-driven actuators with multiple bearing seats and guideways. | Aluminum 7075, Stainless Steel 304 |

| Rotary Servo Motor Mounting Frame | Multi-face housing that aligns stator, rotor, and encoder assembly with exact center offset tolerances. | Aluminum 6061-T6, Cast Iron |

| Precision Worm Gear Carrier | Complex carrier supporting angular gear systems in servo-assisted motion platforms. | Steel 42CrMo4, Bronze Alloy |

| Robotic Arm Joint Segment | 5-axis contoured segment with integrated cable routing channels and bearing pockets. | Titanium Grade 5, Aluminum 7050 |

| Encoder Disc Hub Assembly | Ultra-precise rotating element with optical pattern surfaces and exact alignment for closed-loop control. | Stainless Steel 316L, Invar |

| Part Name | Description | Typical Materials |

|---|---|---|

| Welded Frame Corner Node | Machined after multi-tube welding to achieve perfect joint alignment and mounting surfaces. | Mild Steel, Stainless Steel 304 |

| Laser-Cut Bracket Assembly | Machined from pre-welded laser-cut plates to add threaded features, bevels, and precision holes. | S355 Steel, Aluminum 5083 |

| Tubular Manifold Flange Face | Final surfacing and contouring of complex pipe manifolds to ensure flat flanges and gasket sealing. | Inconel 625, Stainless Steel 316L |

| Heat Exchanger Weldment Block | Complex post-weld machining of port bores, milled slots, and mating surfaces. | Copper-Nickel Alloy, Carbon Steel |

| Custom Robotic Baseplate | Baseplate machined flat and true after fabrication to ensure stability and multi-axis alignment. | Aluminum 6061-T6, Cast Iron |

🌐 General Manufacturing & B2B Sectors

| Part Name | Description | Typical Materials |

|---|---|---|

| Hygienic Mixer Blade Hub | Multi-angled mixing blade connection with smooth surfaces, internal channels, and high polish. | Stainless Steel 316L, Duplex Steel |

| Rotary Filling Nozzle Assembly | Complex nozzle body with intersecting bores, sealing faces, and internal fluid pathways. | 316L Stainless Steel, PEEK |

| Precision Pump Impeller (Sanitary) | Machined impeller with flow-optimized blades and mirror-polished surfaces for clean-in-place systems. | 316L Stainless Steel, Titanium |

| Valve Seat Housing for CIP Systems | Intricate housing with O-ring grooves, bore alignment, and sloped channels to avoid fluid traps. | Stainless Steel 316L, PVDF (if hybrid) |

| Servo-Driven Conveyor Joint Block | Machined joint part with mounting faces, cable routing paths, and recessed sensor pockets. | Aluminum 6082, Anodized 7075, Stainless Steel 304 |

| Part Name | Description | Typical Materials |

|---|---|---|

| Pick-and-Place Robotic Arm Mount | Multi-angled joint block with cable channels, bolt flanges, and curved mating surfaces. | Aluminum 7075-T6, Stainless Steel 304 |

| Precision Linear Guide Baseplate | Complex guide rail base with recessed pockets, dowel pin holes, and precision milled rails. | Anodized Aluminum 6082, Steel 1.7225 |

| Form-Fill-Seal Tooling Block | Milled 3D cavities and sealing contours for pouch or tray sealing in automated packaging lines. | Stainless Steel 316L, Tool Steel 1.2343 |

| Rotary Index Table Hub | Machined central hub for indexing tables with alignment bores, tapped faces, and radial cuts. | Steel 42CrMo4, Aluminum Bronze |

| High-Speed Conveyor Side Bracket | Rigid, lightweight bracket with machined pockets, ribs, and bearing seats for belt systems. | Aluminum 6061-T6, Delrin (Acetal Copolymer) |

| Part Name | Description | Typical Materials |

|---|---|---|

| Injection Mold Core for Lipstick Molds | Precision-polished cavity for forming lipstick sticks, requiring tight surface finish and accurate parting lines. | Stainless Steel 420 (Hardened), Tool Steel H13 |

| Perfume Bottle Blow Mold Insert | Freeform 3D surfaces machined into split mold inserts for complex bottle geometries. | Stainless Steel 316, Aluminum QC-10 |

| Compact Powder Press Die | Intricate upper and lower dies for powder pressing systems with mirror-polished curved profiles. | Tool Steel 1.2379, Polished Stainless Steel |

| Airless Pump Nozzle Housing | Multi-bore component with tight concentric tolerances and sealing seats for skincare pumps. | Stainless Steel 304/316L, PEEK |

| High-Speed Labeling Spindle | Rotational carrier for bottles or caps during labeling, with tight tolerance fit and smooth surface finish. | Aluminum 7075-T6 (Anodized), Stainless Steel 303 |

| Part Name | Description | Typical Materials |

|---|---|---|

| Seed Metering Disc Hub | Precision-machined rotating disc with milled cavities and seed drop ports requiring concentricity. | Stainless Steel 304, Hardened Tool Steel |

| Variable Spray Nozzle Body | Multi-port nozzle with angled channels, internal cone geometry, and external threads. | Brass, Stainless Steel 316 |

| Tractor PTO Gearbox Housing | Complex multi-surface housing with mounting flanges, bearing seats, and oil channels. | Cast Iron GGG50, Steel 42CrMo4 |

| Precision Linkage Arm for Harvesters | Contoured arm with multi-axis bores and reinforced ribbing, used in moving mechanisms. | High-Tensile Steel, Aluminum 7075 |

| Soil Sensor Probe Holder | Compact enclosure with angled pockets and sealing surfaces for embedded agri-sensors. | Stainless Steel 316L, POM-C (Hybrid assemblies) |

| Part Name | Description | Typical Materials |

|---|---|---|

| Suspension Bogie Link Arm | Curved multi-axis structural arm with machined bearing seats and shock absorber mounting points. | High-Strength Steel (42CrMo4), Cast Steel GS-45 |

| Brake Caliper Mount Bracket | Precision bracket with 3D curves and tight-tolerance alignment surfaces for high-speed braking. | Steel 30CrNiMo8, Stainless Steel 304 |

| Pantograph Base Housing | Complex base plate for current collectors with intersecting pockets and dynamic mounting holes. | Aluminum 7075-T6, Stainless Steel 316 |

| Wheel Hub End Cap (Axle Side) | Round, internally-featured hub cover with deep bores and locking geometry. | Cast Iron EN-GJS-500-7, Steel C45 |

| Control System Heat Sink Block | Machined block for power electronics with intricate cooling channels and sensor pockets. | Aluminum 6063-T5, Copper-Inlay Hybrid |

| Part Name | Description | Machinable Materials (CNC-Suitable) |

|---|---|---|

| Ornamental Column Capital | Highly decorative classical capital for pillars, often based on 3D scanned heritage details. | Aluminum 5083 / 7075, High-Density Ureol |

| Custom Facade Relief Panel | Wall-mounted ornamental panels with freeform 3D carvings and artistic contours. | Aluminum 6061, Engineering Plastic (POM, HDPE) |

| Restoration Arch Keystone Insert | Precision-machined insert for arch stabilization, featuring mating contours. | Brass, Aluminum Bronze, Aluminum 6082 |

| Architectural Cornice Bracket | Bracket with scrolls and organic contours for structural or decorative support. | Aluminum 7075, Delrin (POM-C), Engineered Wood Substitute (e.g., Trespa) |

| Decorative Window Frame Section | Machined baroque or gothic trim profiles with multi-face milling and symmetry. | Aluminum 6063-T6, CNC-grade Birch Ply (mockup), POM |

| Part Name | Description | Typical Materials |

|---|---|---|

| Articulated Boom Arm Joint Block | Multi-face machined joint with bearing seats, hydraulic channels, and reinforcement ribs. | Steel 42CrMo4, Aluminum 7075 |

| Excavator Tiltrotator Coupling Plate | Complex contoured interface that mates hydraulic tools with rotating heads. | Hardened Steel (58 HRC), Steel S355 |

| Crane Pulley Sheave Core | Machined core with deep curved grooves, weight-relief pockets, and concentricity tolerance. | Cast Steel, Stainless Steel 304 |

| Bridge Bearing Housing | Multi-axis base with sloped load paths and precision-machined mating surfaces for elastomer bearings. | Steel 1.7225, Aluminum 5083 |

| Concrete Formwork Anchor Block | Custom-shaped high-strength blocks with inclined holes and locking grooves for reusable mold systems. | Stainless Steel 316L, Tool Steel 1.2312 |

| Part Name | Description | Typical Materials |

|---|---|---|

| Miniature Eiffel Tower Support Core | Highly detailed 3D replica with internal supports and lattice structure, milled from solid. | Aluminum 7075-T6, Brass |

| Statue of Liberty Mini Torso | Precision sculpture with flowing drapery, torch arm detail, and facial features requiring multi-axis milling. | Aluminum 5083, Bronze Alloy |

| Basketball Hoop with Integrated Backplate | Full assembly with precision rim curvature, bolt patterns, and reinforced backplate. | Stainless Steel 304, Aluminum 6061 |

| Skatepark Rail Mount Bracket | Contoured base for skate rails with embedded bolt guides and anti-slip grooves. | Steel 42CrMo4, Aluminum 7075 |

| Amusement Ride Track Transition Block | Complex geometry transition block with cambered curves and multi-angle bolt interfaces. | Steel S355, Aluminum 5083-H111 |

📈

Production Volume Tiers

| Category | Range / Detail |

|---|---|

| Units per run | 1 – 100 pcs. |

| Units per year | Up to ~1,000 pcs/year. |

| Typical Use | Prototyping, toolmaking, aerospace, medical. |

| Tooling | Standardized cutting tools and toolpaths, tool life monitoring. |

| Fixturing | Modular or soft fixturing, quick-change 5 axis baseplates, high reusability, manual alignment. |

| Inspection | Inspection on CNC machine - manual probing, manual calipers, micrometers, CMM inspection for GD&T tight tolerances, 3D scanning for complex geometries. |

| R-POL available | Yes. |

| Category | Range / Detail |

|---|---|

| Units per run | 100 – 1,000 pcs. |

| Units per year | ~1,000 – 10,000 pcs/year. |

| Typical Use | Industrial components, automotive, robotics, consumer products, defence. |

| Tooling | Special cutting tools, optimized toolpaths and G&M codes, tool life monitoring, sister tools. |

| Fixturing | Semi-dedicated fixtures, quick-change 5 axis baseplates, mechanic/hydraulic clamps for reduced setup time, soft automation, |

| Inspection | Inspection on CNC machine for every X cycle – automated probing. CMM inspection for GD&T batch inspection, SPC (Statistical Process Control), 3D scanning for complex geometries, Go/No go devices are built. |

| R-POL available | Yes. |

| Category | Range / Detail |

|---|---|

| Units per run | 5,000 – 100,000+ pcs. |

| Units per year | 500,000+ pcs/year. |

| Typical Use | Automotive Tier 1, electronics, massive industrial production projects. |

| Tooling | Special cutting tools and tool coatings, optimised toolpaths and G & M codes, tool life monitoring, sister tools. |

| Fixturing | Dedicated fixtures and clamping devices, custom go/no-go nests, fully automated handling integration. |

| Inspection | 3D scan or CMM used for first article inspection (FAI) or PPAP, inline gauges and dedicated go/no-go systems are built, machine vision automated systems are deployed for 100% control. |

| R-POL available | Not currently available, but possible upon agreement for long-term cooperation. |

| Industry | Low Volume Example | High Volume Example |

|---|---|---|

| Aerospace | 5–50 pcs | 1 000 pcs/year |

| Medical | 10 pcs | 10 000 pcs/year |

| Automotive | 1 000 pcs | 100 000 pcs/year |

| Electronics | 500 pcs | 500 000+ pcs/year |